Timm’s Fitting BMW Alloy Wheels The Easy Way

It’s time for the winter alloys - here’s the easy way to change wheels without breaking stuff

I hate jacking-up cars to change a wheel, lifting a car that weighs over two tons is fraught with danger. Here’s the method I use that

makes everything a lot easier and safer - all you need is a ramp, not even a pair, just the one! Here we go then, I’m starting with the

nearside rear, so stick the ramp in front of the other wheel on that side

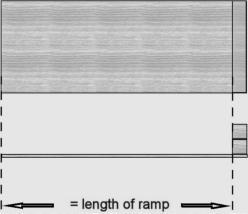

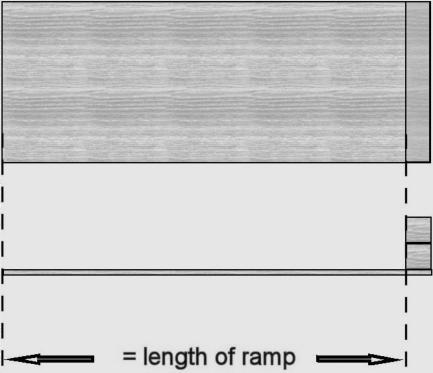

To stop myself going too far up the ramp I use a length of plywood with a couple of 2” x 2” bits of wood stuck on the end - the length

of plywood is the same as the ramp - I stick the ramp-stop on the drivers side where I can see it - when I’m fully up the ramp the 2” x

2” bits of wood stops the car going any further - hopefully that’s the last time I go ever the end of the ramp!

With one of the wheels up the ramp there is little pressure put on the other so it is easy jacking it up. Before jacking the car up

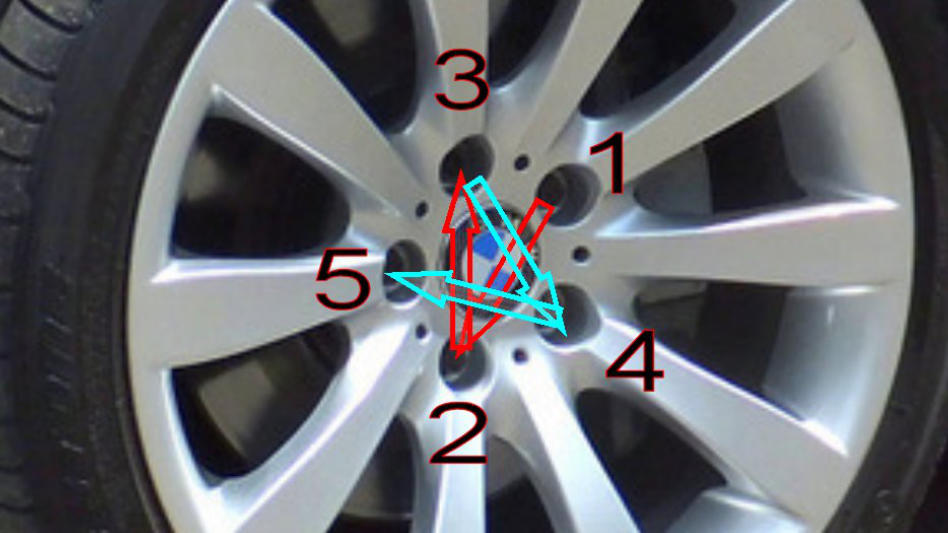

completely remove the locking lug-bolt and loosen the remaining four lug-bolts so that they can be rotated with a plain wrench.

The standard lug-bolts on all BMW’s (except the 4x4’s) are 17mm.

I’m using a torque wrench as it is long enough to give excellent leverage - the longer the better

With the remaining lug-bolts loosened, jack the car up under the jacking pad - you need at least a 2.5 Ton jack to be on the safe

side. Here’s the jacking pad:

Important: When using a trolley jack it is imperative that the jack wheels are free to move. If the jack cannot move

towards the car as it is lifted the car will distort the jacking point and may slip off the jack entirely.

This is because the jack pivots near the handle, and the end of the jack arcs upwards rather than just lifting straight up. The car

pivots in the other direction. This has caught me out before where I thought I would protect the drive with some wood - and then

found that the jacking pad had completely distorted and the car was just about to drop off the jack:

Phew - that was a close one - my 840ci very close to dropping off the jack with the jacking pad completely mangled

Anyway, enough of the scare stories, with the car jacked up to give a 1” clearance under the wheel, remove the remaining bolts

With all the lug-bolts removed give the top of the tyre a sharp pull to remove the wheel from the hub - don’t just heave at it as

the car is on the jack - if the wheel refuses to come off there is a simple trick: Use the replacement wheel to run into the edge of

the alloy you are trying to get off - this not only can’t do any damage to the alloy it is also very effective. If it doesn’t come off

first time, do the same on the other side - it will soon come loose:

Give the hub a quick smear with anti-seize and offer up the replacement alloy so that it sits on the hub - I have one lug-bolt

fitted so that I can rotate the alloy to match the bolt holes

As long as the wheel only needs to be lifted an inch or so this is quite easy to do. Use a plain wrench to tighten the bolts enough

to get the wheel flat on the hub - and then lower the jack

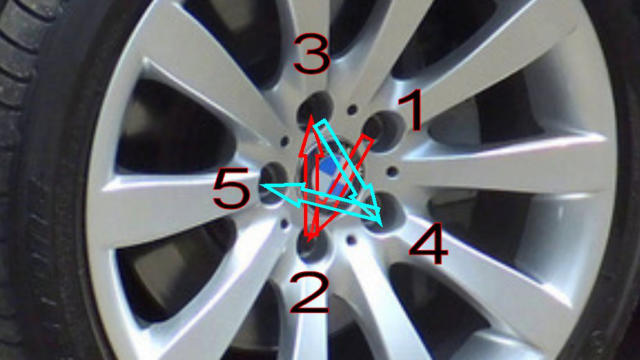

Now tighten the bolts in a cross-pattern.......

...until they are all tightened to 90lb/ft or 120 newton-metre using a torque wrench. If you haven’t got a torque-wrench then

they need to be tightened so that a reasonable effort is made on a 18” wrench

And that’s about it - drive back off the ramp and move onto the next wheel - quite an easy and safe job. I’m

ready for the winter - well, except for the fact that it’s warmed up to a balmy 10C at the moment!

All done, Time for A Cup Of Tea