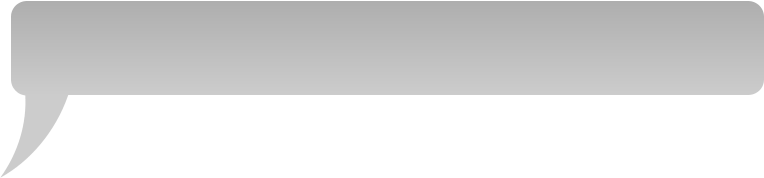

MAF

THROTTLE

BODY

FUEL

INJECTO

R

LAMBDA

SENSOR

ECU (Engine computer)

To catalytic converters

and exhaust system

Fresh air from air filter

MAF

THROTTLE

BODY

FUEL

INJECTOR

LAMBDA

SENSOR

ECU (Engine computer)

To catalytic converters

and exhaust system

Fresh air from air filter

Timm's BMW Engines - Diagnostics and Adaptations

What are they all about and how to fix engine running problems

This is a big subject - engine running problems and adaptations - especially ‘adaptations at limits’ which light up the engine warning lamp.

There is loads of advice on the Forums that say ‘you need diagnostics’ - but what do you actually do with diagnostics - and what do all

those values mean? This document is for those that have engine running problems and want to fix them with the help of diagnostics - in

this case we are using INPA. To get us going we are going to have to understand adaptations first!

ADAPTATIONS

Looking at the stored adaptation values gives us a good insight into the condition of the engine and the source of the problems you may

be having - so we are going to have to understand them first. And to do that we are going to look at a single cylinder of our engines and

ignore all the other sensors. All we are interested in is the basic fuel/air mixture which is provided by measuring air MASS (with a MAF

sensor) - the ECU (engine computer) then computes how long to open the injector for:

input 1 gram of air per rev

output 10ms injector duration

So, above is the very basic plan - measure the air input and decide on how long to open the injector - this happens every camshaft

revolution. The target is to get the fuel/air ratio correct because this provides efficient combustion and clean exhaust gasses.

But, it is pretty obvious that there are going to be errors, and early engines had an adjustment for the air measuring device (which was

an AIRFLOW METER rather than a MAF) so that you could compensate for wear, air leaks, blocked injectors and a myriad of other

possibilities. So - engine manufacturers added a way of checking the fuel/air mixture by using a Lambda (Oxygen) sensor.

The Lambda (Oxygen) Sensor saves the day

Ignoring all the subtleties, a good combustion will produce an Oxygen level at the exhaust that is equal to that of the surrounding air -

Lambda sensors measure the difference in Oxygen concentrations between the outside air and that in the exhaust. If the mixture is too

lean (not enough fuel) the fuel is all burnt before the available Oxygen is consumed - and if the mixture is too rich (too much fuel) then

all the Oxygen is consumed leaving unburnt fuel.

The Lambda’s used on the M60/M62/M62TUB engines are narrow band and inform the engine if the Oxygen level is too low - or too high

which relates to a mixture that is too rich or too lean respectively. But, these short-term deviations are not important, the ECU filters the

Lambda output to determine if the mean value is correct. (INPA will show you the live output from the Lambda sensors, you will see the

output swinging around - you will also see the integrated output which shows the filtered value).

So, let’s add the Lambda to the engine below, at the moment everything is Hunky Dory:

That’s spot-on mate!

input 1 gram of air per rev

output 10ms injector duration

There we go, we didn’t need that Lambda sensor after all - well until things wear and leak - let’s start with the

most obvious problem and the most common - air leaks

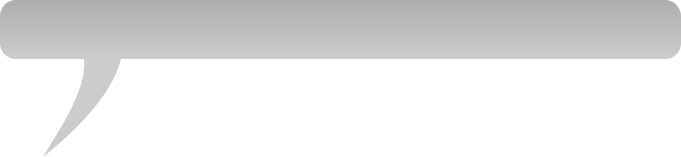

MAF

THROTTLE

BODY

FUEL

INJECTO

R

LAMBDA

SENSOR

ECU (Engine computer)

To catalytic converters

and exhaust system

Fresh air from air filter

That’s miles too lean - add more

fuel next time mate!

input 0.5 grams of air per rev

output 5ms injector duration

We’ve added an air-leak, if the leak was after the throttle body we would call it a vacuum leak. The Lambda system has noticed that the

Oxygen level is too high and that indicates the mixture is too weak. This is where Adaptations come into play. To compensate for the un-

metered air the ECU is going to increase the injector time (dwell) to richen the mixture.

This compensation is not immediate, instead, over thousands of engine revolutions the injector duration is slowly increased. These

compensations are called ADAPTATIONS and are stored in the ECU so that when the engine is re-started the information is available to be

used. Note: The M60 engine adaptations only remained when battery power was available - disconnecting the battery would clear all

adaptations (called a Magic Reset) - the M62 ECU stored Adaptations in Flash Memory and could not be simply erased.

Air leak at

manifold, PCV,

gaskets, boots

etc

•

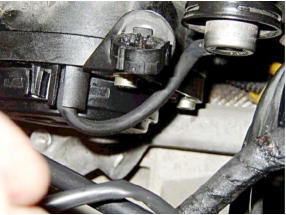

Lambda-Probe Voltage - This is the raw output from the Lambda probe - in this case we are looking at Bank 1 which is right

hand bank (when viewed from behind the car). Lambda probes do nothing at all until they have reached operating temperature

and this value will stay stationary for a couple of minutes - it then should start moving around the scale. Due to the refresh rate of

the screen you will not see it move smoothly, nor will you see that it is actually a sinusoidal waveform - instead it will just seem to

flap around a bit.

When the engine is at operating temperature the Lambda sensor is informing the ECU of the remaining Oxygen level in the exhaust

- and that, in turn, indicates the initial air/fuel mixture. The M60/M62/M62TUB engines employ narrow band Lambda sensors which

mean they can only indicate a mixture is too weak or too lean. The ECU continually makes small adjustments to the injector dwell

in response to the raw Lambda output - for example, the Lambda will report that the mixture is too weak and the ECU will increase

injector dwell (the time it is open) - it does this in tiny increments - until the Lambda signal ‘flops’ high indicating that the mixture

is too rich.

This behaviour is normal operation for all models with narrow-band Lambda sensors. Later models with the N62 engine variants

have wide band Lambda sensors and they behave completely differently reporting absolute Oxygen levels and don’t flop about.

On both types, a zero value indicates that the sensor has failed short-circuit and the ECU will store an error message. In this

situation the ECU ignores the Lambda value and instead uses other sensors (such as the throttle position sensor and MAF readings)

to estimate the correct air/fuel mixture.

Lambda sensor rarely fail, but are replaced in their thousands because diagnostics will show a Lambda error of some sort - which

is akin to replacing temperature sensors if the engine is running hot. Later models could report ‘Lambda Ageing’ error codes which

was an indication that they were responding slowly to Oxygen levels - and that was usually because they were covered in soot.

•

Monitor Probe 1 After KAT - some models have additional Lambda sensors AFTER the catalytic converters. These monitor the

performance of the catalytic element which should be storing Oxygen when it is plentiful, and releasing it when the Oxygen levels

drop below that of atmospheric levels. What you expect to see at this point is a slight change in Oxygen levels which will follow the

pre-cat sensor (but delayed by the Oxygen-holding capacity of the catalytic element) - but at a much lower amplitude. If the

catalytic converter has failed this sensor will follow the pre-cat sensors at the same amplitude - the ECU would then decide the

catalytic element had failed and bung up an error code. Models such as the E31 don’t have these fitted and the value stays

stationary at around 0.8V. The values reported do not affect the air/fuel ration - although a blocked cat does!

•

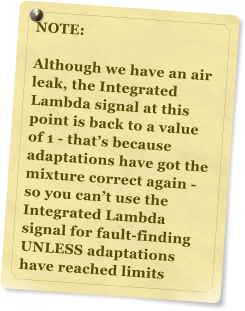

Lambda Intergrator - This is the filtered and integrated output from the pre-cat Lambda sensor. The raw sinusoidal output from

the sensor is low-pass filtered and then referenced to a value of 0. What all that blurb means is that if the fuel/air mixture is

correct then we would expect to see a value of around 0.00 here. A higher value indicates a LEAN mixture, a lower value indicates

a RICH mixture - it’s as simple as that! This flops all over the place as the Lambda sensors reach operating temperature so ignore

that bit, once the engine has reached operating temperature this will change value by small amounts but centre around 0.00

If the adaptations were deleted we would expect this value to deviate from 0.00 (unless the engine was absolutely perfect) - and

we would expect to see the adaptations slowly changing in value until we get to a point where the adaptations have managed to

get this value back to 0.00. If this does not happen then the ECU will report ‘adaptations at limits’ and bung on the check engine

warning lamp.

•

Adaption Value Additive - If the Lambda Integrator reports that the mixture is too lean (at

idle) then the ECU will slowly increase this value to increase the injector dwell so that the

mixture enriches. If you have a value here that it greater than +10 you can be sure you have

a vacuum leak - or the MAF is mis-reporting the actual air mass.

If the value here moves to less than -10 (especially if combined with a negative value for the

multiplicative adaptations) that usually points to a failure of the vacuum pipe that runs

between the PCV and the Fuel Pressure Regulator (FPR) - at idle the PCV will be supplying a

vacuum to the FPR which limits the fuel-rail pressure to 3.0 Bar - if that vacuum is missing

(the pipe is kinked, torn or missing) then the fuel-rail pressure will increase to 3.5 Bar and

adaptations will be seriously skewed trying to pull the fuel/air mixture back to the correct

levels. A slightly negative reading indicates less than perfect combustion (plugs, coils)

•

Adaption Value Multiplicative - This value is modified if the mixture is not ideal at higher engine loads and speeds (when

cruising for instance). If this one moves to far away from 1.00 then things are not right - a vacuum leak is much less likely as the

manifold vacuum reduces with engine load and that proportionally reduces its influence. However, a large additive and small

multiplicative positive increase does point towards an air or vacuum leak.

A large negative number here could be excessive fuel-rail pressure - but it could also be poor combustion in one or more cylinders

- the smoothness values would help us differentiate the two possibilities

SMOOTHNESS

(also know as roughness on some models)

Practical measurements using INPA diagnostics

The three important screens that will find most running problems

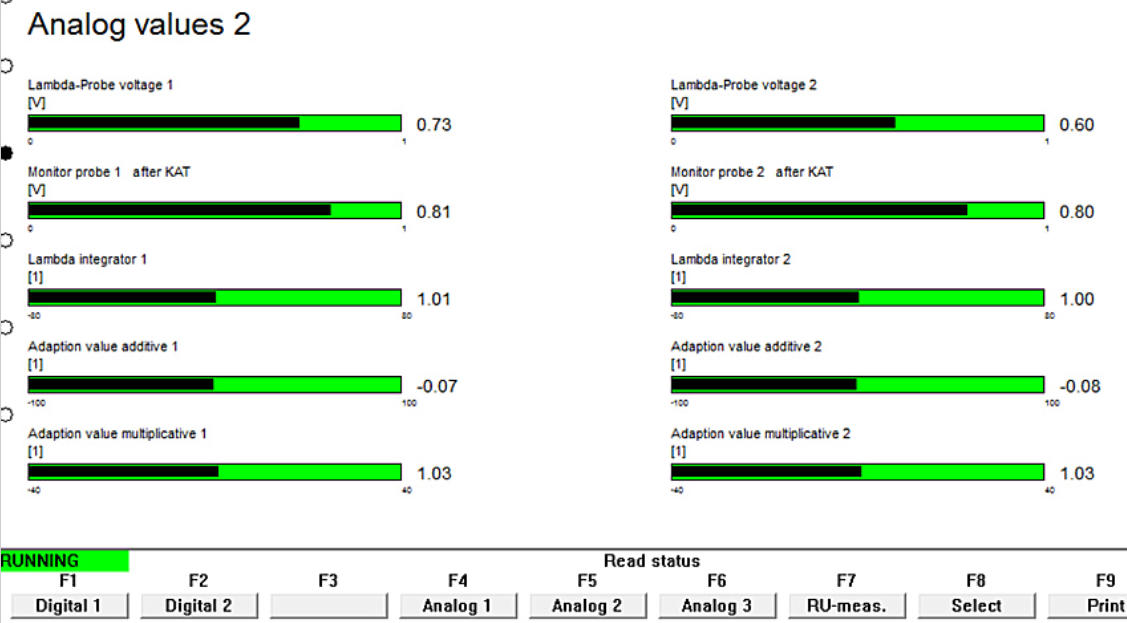

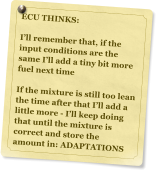

ANALOG VALUES 2

Lambda Sensors and Adaptation values

Right, we know what Adaptations are now - they are values learnt by the ECU to compensate for imperfections, and that includes

imperfections with the sensors as well as mechanical problems such as air and vacuum leaks. Let’s have a look at an INPA screenshot

(Analog value 2) from an M62TUB44 after it has reached operating temperature (I’ve annotated Bank 1):

RAW output from the Lambda sensor BEFORE the catalytic converter. This is a measurement of

the remaining Oxygen in the exhaust gasses and indicates the fuel/air mixture before combustion

This (should) constantly change in voltage (0.2V - 0.9V)

Raw output of Lambda AFTER the catalytic converter - this effectively measures catalytic

converter condition. We will ignore this value as it has no bearing on adaptations

Integrated Lambda signal, it is an indication of fuel/air mixture with less flopping

about - if the mixture is correct this will settle at around 0. A positive value indicates a

LEAN mixture. With a stable mixture this value should move around a zero value

Additive Adaptation - How much injector dwell is ADDED or SUBTRACTED

So, (say) 10ms + 1ms injector dwell.

This is example is close enough at 0.07

Multiplicative Adaptation - How much the injector dwell is MULTIPLIED by

So, (say) 10ms injector dwell x 2 = 20ms

This is example is close enough at 1.03

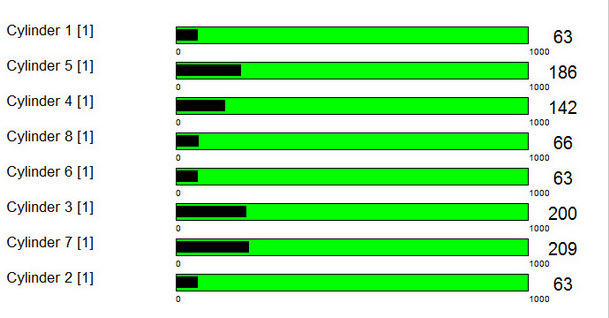

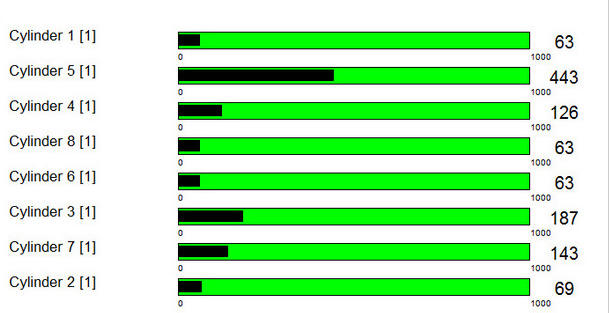

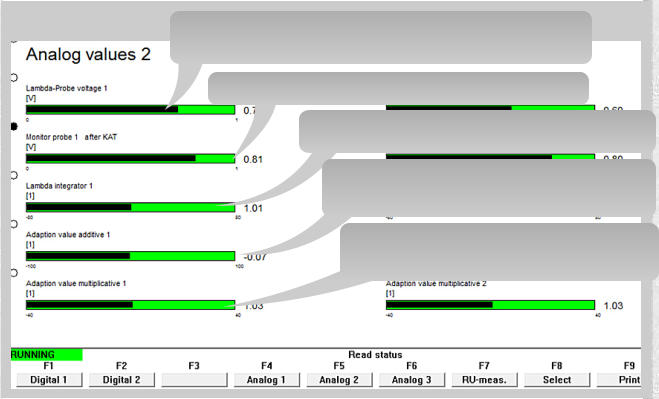

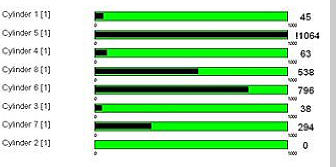

The SMOOTHNESS VALUE is an indication of the

consistency of providing crankshaft acceleration at idle for

each cylinder. If that effort was the same every camshaft

revolution then the value would stay at ZERO (a completely

dead cylinder will give a zero reading)

As cylinder combustion is never perfect you will get

differing levels of effort being made for the same cylinder -

the greater that difference the higher the smoothness value

(a dodgy cylinder will give a higher reading)

This example is of a healthy engine, lower values can be

seen, especially if you restart diagnostics when the engine

is running (usually the source of ‘my engine is very

smooth’ screenshots online!)

The screenshot above is from my 840ci, and so is the one on

the left, but before I fixed all sorts of vacuum leaks.

The smoothness and Lambda screens showed that things

were not happy - my first plan was to swap coils around (as it

is easy to do) to see if cylinder 5 would perk up a bit - but it

didn’t, so I could discount ignition problems

It was the combination of Smoothness and Adaptations that

pointed towards a vacuum leak - using the Smoothness

values ruled out a dodgy ignition coil

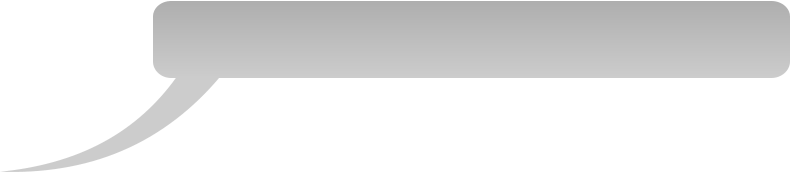

MAF

THROTTLE

BODY

FUEL

INJECTO

R

LAMBDA

SENSOR

ECU (Engine computer)

To catalytic converters

and exhaust system

Fresh air from air filter

That’s spot-on mate!

input 0.5 grams of air per rev

output 5ms injector duration

PLUS ADDITIVE ADAPTATION of 5ms

That’s basic adaptation at work - although the MAF measured only 0.5 grams of air per revolution the ADAPTATIONS have requested an additional 5ms injector

duration. It took quite a while for adaptations to work themselves up to this point (if a large air-leak is introduced it may take ten minutes at idle for adaptations

to pull the mixture back correctly). But, now the fuel/air mixture is correct (but only at this engine speed and load) and all is jolly.

The EVIDENCE that something is wrong is that the Additive adaptations will be quite noticeable - if the air-leak was large enough (like this example is) then you

will get an engine warning lamp lit and INPA will show ‘adaptations at limit’. However, as long as the ECU has done its job correctly there should be no misfire, the

engine will be as smooth as normal as the mixture is now correct again.

Additive and Multiplicative Adaptations

I’ve seen a couple of documents regarding when these two adaptation types are modified - the blurb says:

•

Additive adaptations are made at IDLE, LOW LOAD and LOW TO MID RANGE ENGINE SPEEDS

•

Multiplicative adaptations are made at NORMAL TO HIGHER LOADS when at HIGHER ENGINE SPEEDS

But, my experience of the M62B44 shows that the Multiplicative adaptations can be modified at idle when the Additive adaptations reach their limits, so I’m not

sure if the above information is perfectly true! But, it is probably close enough for our purposes. As far as their effects on engine performance is concerned, we

can broadly say that:

•

The Additive adaptations have more effect at idle and only slightly modify the cruising and acceleration performance.

•

The Multiplicative adaptations affect every aspect of engine performance and that includes idle

Air leak at

manifold, PCV,

gaskets, boots

etc

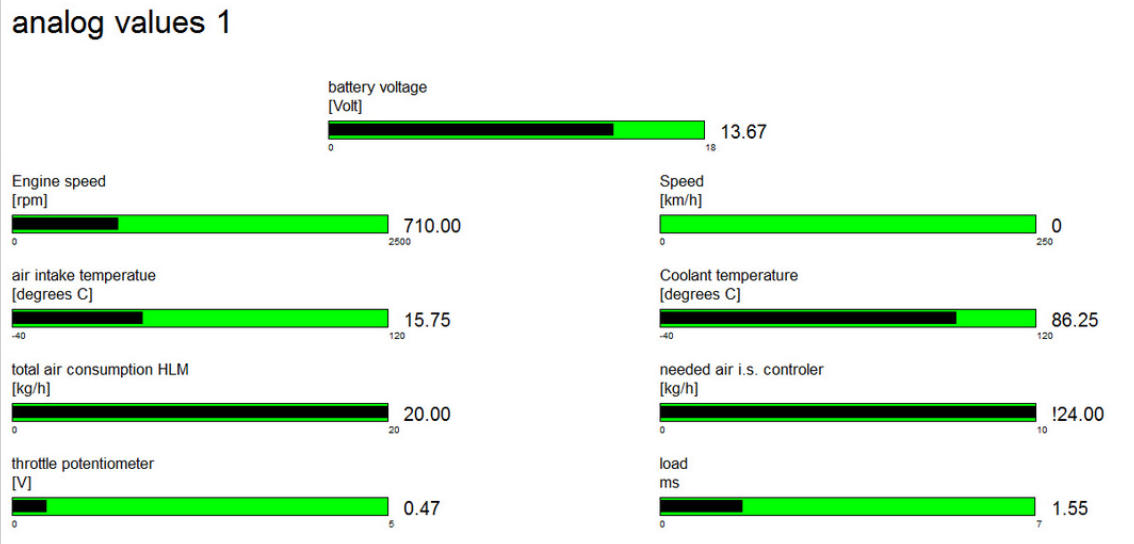

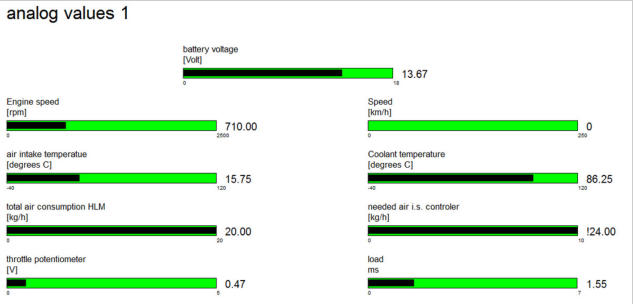

This is the correct temperature

when the M62 is fitted to an E31 -

The E38 has a mapped thermostat

and at idle the temperature should

be 105C - 108C

The ECU has

calculated that the

ICV (Idle-speed

Control Valve)

needs to open

sufficiently to pass

24Kg/h - this value

causes much angst

as it often has the

(!) warning - but

this value is within

limits

Total air consumption

On the V8’s it should be

around 20Kg/h as seen here.

When the engine is cold it is

normal to get a warning (!) -

the slider scale was designed

for lesser engines!

This engine speed is

normal if A/C is ON - if

A/C is OFF it should be

around 550-600 RPM

Don’t bother diagnosing

problems if the running

voltage is less than 12.6V

The screen above is always a good place to start when things aren’t running nicely - it gives a good indication of the basic sensors:

•

Battery Voltage - with the engine running we expect a voltage between 12.6V to 14.6V. Anything below 12.6V means that

something is wrong with the alternator and low voltages will cause ignition problems - so get that bit fixed first!

•

Engine Speed - On the M60, M62 and M62TUB the engine revs should be 550 - 600 with the A/C OFF. If the A/C is switched ON

and working then the revs should increase to 700.

•

Air Intake Temperature - On the M60 engine this temperature sensor is stuck on the RHS of the intake manifold, on the M62

engine it is incorporated into the MAF - although on some models there is an additional sensor on the air filter housing. The

reported temperature should be around the ambient temperature plus a few degrees. If the temperature is mis-reported this will

cause the adaptations to move away from the ideal. Replace the MAF if the error is more than five or six degrees out. However, on

the N62 engines this value is often much higher even on new MAF’s.

•

Coolant Temperature - This is the coolant temperature of the ENGINE. On some models the radiator outlet temperature is also

reported - we are not interested in that when finding engine running problems. The engine must be at running temperature for

basic diagnostics. Although the M62 engine is used across a few models, the coolant temperature is lower when used in the E31 as

this has a fixed 85C thermostat - whereas the E38 and E39 have a temperature-mapped thermostat with a passive opening

temperature of 104C - at idle the reported temperature would be around this value. When performing diagnostics (unless you are

looking for cold-start problems) it is imperative that the engine reaches operating temperature - and if the engine fails to reach the

thermostat opening temperature then that could well be the source of the engine performance problems

•

Needed Air I.S. Controller - On the M60 and M62 (not the TUB version) the idle speed is controlled by an Idle-speed Control Valve

(ICV). The ECU calculates how much air this has to allow through it to maintain the correct idle speed. This is the Needed air i.s.

controller value. Unfortunately the scale (just like that of the Total Air Consumption slider) is too short for the mighty V8’s and

although everything is working perfectly you often (nearly always) get the (!) warning next to it. Don’t panic, this is perfectly

normal for the V8’s

•

Total Air Consumption HLM - This is the airflow that the MAF is reporting. This often causes angst because a warning (!) is

shown. But, as long as this value is around 20Kg/h - 25Kg/h then everything is fine for the V8’s. Just like the previous slider, the

scale seems to have been made too short for the larger engines. If diagnosing the car from cold this value will be much higher and

the warning (!) will be shown, again, this is perfectly normal. The lack of a value here means that the MAF is not connected or has

failed. If the value is less than 18Kg/h when the engine is hot that will indicate a vacuum leak, possibly around the inlet manifold.

Readings that are absolutely miles out usually indicate a failed MAF

•

Throttle Potentiometer - this is the voltage reported from the throttle position sensor which is fitted to the throttle body on the

M60 and M62. The M62TUB has a motorised throttle body (as does the N62) but this value has been retained and is interpreted

from the EML system rather than directly from the throttle body. A voltage around 0.45V is expected - plus or minus 0.1V. As the

throttle is pressed this value will increase. Due to the refresh rate of the diagnostic screen the value will move in a jerky fashion -

unless the value jumps backwards as the throttle is increased then the potentiometer is probably OK.

On the M60 and M62 this value is reported from the throttle body

potentiometer. This value will move if the throttle is opened -

around 0.45V is expected at idle

ANALOG VALUES 1

Primary and secondary engine sensors

OPEN - LOOP MIXTURE

CONTROL

CLOSED - LOOP MIXTURE

CONTROL

AIR LEAK

INTRODUCED

ADAPTATIONS

COMPENSATE

HOW ENGINE PROBLEMS AFFECT THE READINGS

So, we know a lot more about how to use diagnostics and what each of the screens can show us if we have an engine running problem.

Obviously, if you have a part of the engine that has completely died (such as a coil-pack) then error codes are stored, and then repair is

straightforward - and you probably won’t be reading this. But, when parts sort of work but not properly then these three screens will help

us whittle the possibilities down. Let’s have a quick look at problems and how they affect the readings.

•

Oil in the sparkplug wells (details and repair information here)

This problem causes misfires on single cylinders rather than an overall lumpiness of all 8 cylinders. If the coil completely failed we

would find a stored error code, and the ECU would inhibit the injector on that cylinder to stop unburnt fuel getting to the catalytic

converters. But where it fires feebly and intermittently we can find evidence on both Adaptations and Smoothness. We would expect to

see an increase in the smoothness value for that cylinder AND the Additive Adaptations would be below zero as they

compensated for the partially combusted fuel

•

Failing catalytic converter (details and repair information here)

Catalytic converters can fail in a way that blocks the flow of exhaust gasses - either by melting or disintegrating. When they

disintegrate parts of the honeycomb can become detached and block the outlet from the converter casing. In this situation the error

happens quite quickly, the car starts shaking and power is lost - but when the car is stopped the errant bit of honeycomb of falls away

from the outlet and all is good when re-started. Where the honeycomb melts the exhaust flow is reduced and so is engine power - but

the evidence it leaves is quite noticeable. This is one of the few errors that shows adaptations completely different between the

two Banks - one will be positive, the other negative. The reason for this is that we only have one MAF - and two banks. If the flow

of gasses is inhibited on one bank then that bank becomes richer, and the other leaner. It is also possible to get knock sensor error

codes when things get badly blocked.

•

Vacuum leaks around the manifold gaskets (details and repair information here)

Manifold leaks can affect the smoothness of single cylinders and adjacent cylinders along with an increase of Additive

Adaptations. This is due to the construction of the gaskets which serve two adjacent cylinders and the design of the one-piece inlet

manifold. The difference between faulty coil packs and manifold leaks is that the latter increases Additive Adaptations whereas a faulty

coil pack (well, until it gives up completely) reduces the adaptations.

•

Fuel pressure regulation problems (details mentioned in this article)

The TIS always mentions fuel-rail pressure as the first thing that is checked if you have engine running problems. But, as a general

rule they are pretty well behaved. But they do two things that really upset the engine. They can leak internally and that pushes raw

fuel directly into the manifold via the vacuum pipe that runs between the FPR and the PCV. That makes starting the engine difficult as

the manifold is flooded - but as far as diagnostics go it pushes the Additive Adaptations negative and affects the Multiplicative

Adaptations in a much lesser way. If the pipe is removed it will be found to be wet with fuel.

The pipe between the FPR and the PCV can be punctured and this has the effect of increasing fuel-rail pressure to 3.5 Bar (instead

of 3 Bar) and that will increase the amount of fuel that is added in all engine ranges except full throttle. In this situation Additive

Adaptations will be very negative and Multiplicative Adaptations will be negative to a lesser extent. A quick check for this

problem is to pinch the vacuum pipe and remove the FPR end - if the engine note does NOT change the pipe is blocked, puncture or

the FPR is faulty.

•

Vacuum leaks on external manifold parts (details and repair information here)

These leaks can be around the throttle body, around the PCV gasket, the vacuum lines to the brake booster and then capped off

service ports as mentioned in the article above. These leaks are easily compensated for by adaptations and the clue is that Additive

Adaptations are positive, and Multiplicative Adaptations are positive to a much lesser extent. Quite often the engine is

perfectly happy until the adaptations reach their limits.

•

MAF problems (discussed here)

The MAF always gets the blame - and the usual advice is to disconnect it and see if the engine runs better - and it quite often does.

With the MAF disconnected the other sensors take the primary role - the throttle potentiometer being the primary airflow sensor. But,

if you want to do this test correctly - switch off the car, ignition back ON, use diagnostics to clear the engine adaptations, disconnect

the MAF, switch the ignition OFF and then re-start the car - how’s it running now? Using this method will show if the default engine

values give good performance, and if they do the MAF is suspect. If the engine runs badly then the fault is elsewhere.

Faulty MAF’s can cause all sorts of problems - but the signature of a failed MAF is very high adaptations, quite often with Additive

Adaptations being negative and Multiplicative Adaptations being positive. There is often a lack of performance, especially under

harsh acceleration where the Lambda sensor has no effect at all.

•

PCV failure (details and repair information here)

Not all PCV failures cause smoke, some just let lots of un-metered air in (they usually make a whistling noise at the same time).

Sometimes they just let a small amount of air in and these leaks are easily compensated for by adaptations and the clue is that

Additive Adaptations are positive, and Multiplicative Adaptations are positive to a much lesser extent. Quite often the engine

is perfectly happy until the adaptations reach their limits. However, they usually get worse to a point where you get several misfires,

especially on a cold start.

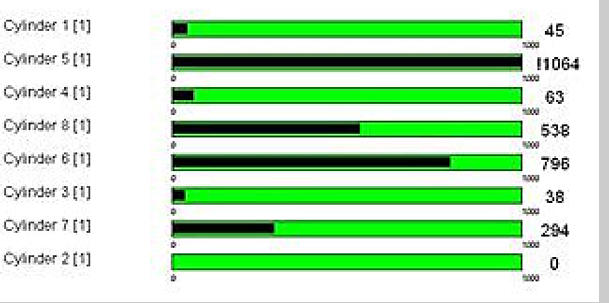

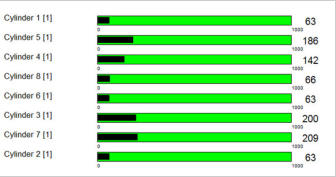

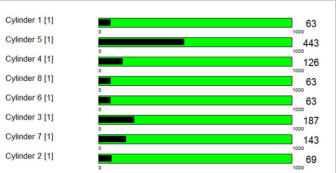

That’s obviously not right at all! I trawled this from the

internet as an example. I would expect that the Adaptations

were at limits on this example as cylinder 5 is hardly firing

consistently. Where a cylinder fires inconsistently there will

be unburnt fuel getting to the Lambda sensor - the ECU will

try and lean-out the mixture but that will start to affect the

other cylinders

This example is quite interesting as Bank 2 (cylinders 5 - 8)

is badly affected whereas Bank 1 (cylinders 1 - 4) look

pretty happy - although the value of zero on cylinder 2

probably means it’s not doing anything at all. I would try

and get cylinder 2 firing again - but my best guess is that

the catalytic converter is blocked on Bank 2

SEARCH MEEKNET

SEARCH MEEKNET

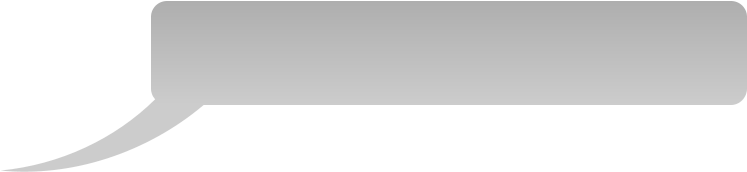

MAF

THROTTLE

BODY

FUEL

INJECTOR

LAMBDA

SENSOR

ECU (Engine computer)

To catalytic converters and

exhaust system

Fresh air from air filter

MAF

THROTTL

E BODY

FUEL

INJECTOR

LAMBDA

SENSOR

ECU (Engine computer)

To catalytic converters

and exhaust system

Fresh air from air filter

Timm's BMW Engines - Diagnostics

and Adaptations

What are they all about and how to

fix engine running problems

This is a big subject - engine running problems and adaptations -

especially ‘adaptations at limits’ which light up the engine warning lamp.

There is loads of advice on the Forums that say ‘you need diagnostics’ -

but what do you actually do with diagnostics - and what do all those

values mean? This document is for those that have engine running

problems and want to fix them with the help of diagnostics - in this case

we are using INPA. To get us going we are going to have to understand

adaptations first!

ADAPTATIONS

Looking at the stored adaptation values gives us a good insight into the

condition of the engine and the source of the problems you may be

having - so we are going to have to understand them first. And to do that

we are going to look at a single cylinder of our engines and ignore all the

other sensors. All we are interested in is the basic fuel/air mixture which

is provided by measuring air MASS (with a MAF sensor) - the ECU

(engine computer) then computes how long to open the injector for:

input 1 gram of air per rev

output 10ms injector duration

So, above is the very basic plan - measure the air input and decide on

how long to open the injector - this happens every camshaft revolution.

The target is to get the fuel/air ratio correct because this provides

efficient combustion and clean exhaust gasses.

But, it is pretty obvious that there are going to be errors, and early

engines had an adjustment for the air measuring device (which was an

AIRFLOW METER rather than a MAF) so that you could compensate for

wear, air leaks, blocked injectors and a myriad of other possibilities. So -

engine manufacturers added a way of checking the fuel/air mixture by

using a Lambda (Oxygen) sensor.

The Lambda (Oxygen) Sensor saves the day

Ignoring all the subtleties, a good combustion will produce an Oxygen

level at the exhaust that is equal to that of the surrounding air - Lambda

sensors measure the difference in Oxygen concentrations between the

outside air and that in the exhaust. If the mixture is too lean (not

enough fuel) the fuel is all burnt before the available Oxygen is

consumed - and if the mixture is too rich (too much fuel) then all the

Oxygen is consumed leaving unburnt fuel.

The Lambda’s used on the M60/M62/M62TUB engines are narrow band

and inform the engine if the Oxygen level is too low - or too high which

relates to a mixture that is too rich or too lean respectively. But, these

short-term deviations are not important, the ECU filters the Lambda

output to determine if the mean value is correct. (INPA will show you

the live output from the Lambda sensors, you will see the output

swinging around - you will also see the integrated output which shows

the filtered value).

So, let’s add the Lambda to the engine below, at the moment everything

is Hunky Dory:

That’s spot-on mate!

input 1 gram of air per rev

output 10ms injector duration

There we go, we didn’t need that Lambda sensor after all - well until

things wear and leak - let’s start with the most obvious problem and the

most common - air leaks

MAF

THROTTL

E BODY

FUEL

INJECTOR

LAMBDA

SENSOR

ECU (Engine computer)

To catalytic converters

and exhaust system

Fresh air from air filter

That’s miles too lean - add

more fuel next time mate!

input 0.5 grams of air per rev

output 5ms injector duration

We’ve added an air-leak, if the leak was after the throttle body we would

call it a vacuum leak. The Lambda system has noticed that the Oxygen

level is too high and that indicates the mixture is too weak. This is where

Adaptations come into play. To compensate for the un-metered air the

ECU is going to increase the injector time (dwell) to richen the mixture.

This compensation is not immediate, instead, over thousands of engine

revolutions the injector duration is slowly increased. These

compensations are called ADAPTATIONS and are stored in the ECU so

that when the engine is re-started the information is available to be

used. Note: The M60 engine adaptations only remained when battery

power was available - disconnecting the battery would clear all

adaptations (called a Magic Reset) - the M62 ECU stored Adaptations in

Flash Memory and could not be simply erased.

Air leak at manifold,

PCV, gaskets, boots

etc

•

Lambda-Probe Voltage - This is the raw output from the Lambda

probe - in this case we are looking at Bank 1 which is right hand bank

(when viewed from behind the car). Lambda probes do nothing at all

until they have reached operating temperature and this value will stay

stationary for a couple of minutes - it then should start moving around

the scale. Due to the refresh rate of the screen you will not see it move

smoothly, nor will you see that it is actually a sinusoidal waveform -

instead it will just seem to flap around a bit.

When the engine is at operating temperature the Lambda sensor is

informing the ECU of the remaining Oxygen level in the exhaust - and

that, in turn, indicates the initial air/fuel mixture. The M60/M62/M62TUB

engines employ narrow band Lambda sensors which mean they can only

indicate a mixture is too weak or too lean. The ECU continually makes

small adjustments to the injector dwell in response to the raw Lambda

output - for example, the Lambda will report that the mixture is too

weak and the ECU will increase injector dwell (the time it is open) - it

does this in tiny increments - until the Lambda signal ‘flops’ high

indicating that the mixture is too rich.

This behaviour is normal operation for all models with narrow-band

Lambda sensors. Later models with the N62 engine variants have wide

band Lambda sensors and they behave completely differently reporting

absolute Oxygen levels and don’t flop about.

On both types, a zero value indicates that the sensor has failed short-

circuit and the ECU will store an error message. In this situation the

ECU ignores the Lambda value and instead uses other sensors (such as

the throttle position sensor and MAF readings) to estimate the correct

air/fuel mixture.

Lambda sensor rarely fail, but are replaced in their thousands because

diagnostics will show a Lambda error of some sort - which is akin to

replacing temperature sensors if the engine is running hot. Later models

could report ‘Lambda Ageing’ error codes which was an indication that

they were responding slowly to Oxygen levels - and that was usually

because they were covered in soot.

•

Monitor Probe 1 After KAT - some models have additional Lambda

sensors AFTER the catalytic converters. These monitor the performance

of the catalytic element which should be storing Oxygen when it is

plentiful, and releasing it when the Oxygen levels drop below that of

atmospheric levels. What you expect to see at this point is a slight

change in Oxygen levels which will follow the pre-cat sensor (but

delayed by the Oxygen-holding capacity of the catalytic element) - but

at a much lower amplitude. If the catalytic converter has failed this

sensor will follow the pre-cat sensors at the same amplitude - the ECU

would then decide the catalytic element had failed and bung up an error

code. Models such as the E31 don’t have these fitted and the value

stays stationary at around 0.8V. The values reported do not affect the

air/fuel ration - although a blocked cat does!

•

Lambda Intergrator - This is the filtered and integrated output from

the pre-cat Lambda sensor. The raw sinusoidal output from the sensor is

low-pass filtered and then referenced to a value of 0. What all that blurb

means is that if the fuel/air mixture is correct then we would expect to

see a value of around 0.00 here. A higher value indicates a LEAN

mixture, a lower value indicates a RICH mixture - it’s as simple as that!

This flops all over the place as the Lambda sensors reach operating

temperature so ignore that bit, once the engine has reached operating

temperature this will change value by small amounts but centre around

0.00

If the adaptations were deleted we would expect this value to deviate

from 0.00 (unless the engine was absolutely perfect) - and we would

expect to see the adaptations slowly changing in value until we get to a

point where the adaptations have managed to get this value back to

0.00. If this does not happen then the ECU will report ‘adaptations at

limits’ and bung on the check engine warning lamp.

•

Adaption Value Additive - If the

Lambda Integrator reports that the

mixture is too lean (at idle) then

the ECU will slowly increase this

value to increase the injector dwell

so that the mixture enriches. If you

have a value here that it greater

than +10 you can be sure you have

a vacuum leak - or the MAF is mis-

reporting the actual air mass.

If the value here moves to less than

-10 (especially if combined with a

negative value for the multiplicative

adaptations) that usually points to a failure of the vacuum pipe that

runs between the PCV and the Fuel Pressure Regulator (FPR) - at idle

the PCV will be supplying a vacuum to the FPR which limits the fuel-rail

pressure to 3.0 Bar - if that vacuum is missing (the pipe is kinked, torn

or missing) then the fuel-rail pressure will increase to 3.5 Bar and

adaptations will be seriously skewed trying to pull the fuel/air mixture

back to the correct levels. A slightly negative reading indicates less than

perfect combustion (plugs, coils)

•

Adaption Value Multiplicative - This value is modified if the mixture is

not ideal at higher engine loads and speeds (when cruising for

instance). If this one moves to far away from 1.00 then things are not

right - a vacuum leak is much less likely as the manifold vacuum

reduces with engine load and that proportionally reduces its influence.

However, a large additive and small multiplicative positive increase does

point towards an air or vacuum leak.

A large negative number here could be excessive fuel-rail pressure - but

it could also be poor combustion in one or more cylinders - the

smoothness values would help us differentiate the two possibilities

Practical measurements using INPA

diagnostics

The three important screens that will find

most running problems

ANALOG VALUES 2

Lambda Sensors and Adaptation values

Right, we know what Adaptations are now - they are values learnt by the

ECU to compensate for imperfections, and that includes imperfections with

the sensors as well as mechanical problems such as air and vacuum leaks.

Let’s have a look at an INPA screenshot (Analog value 2) from an

M62TUB44 after it has reached operating temperature (I’ve annotated Bank

1):

RAW output from the Lambda sensor BEFORE the catalytic converter. This is a

measurement of the remaining Oxygen in the exhaust gasses and indicates the fuel/air

mixture before combustion

This (should) constantly change in voltage (0.2V - 0.9V)

Raw output of Lambda AFTER the catalytic converter - this effectively measures

catalytic converter condition. We will ignore this value as it has no bearing on

adaptations

Integrated Lambda signal, it is an indication of fuel/air mixture with less

flopping about - if the mixture is correct this will settle at around 0. A positive

value indicates a lean mixture. With a stable mixture this value should move

around a zero value

Additive Adaptation - How much injector dwell is ADDED or

SUBTRACTED

So, (say) 10ms + 1ms injector dwell.

This is example is close enough at 0.07

Multiplicative Adaptation - How much the injector dwell is

MULTIPLIED by

So, (say) 10ms injector dwell x 2 = 20ms

This is example is close enough at 1.03

SMOOTHNESS

(also know as roughness on some models)

The SMOOTHNESS VALUE is an indication of the

consistency of providing crankshaft acceleration at

idle for each cylinder. If that effort was the same

every camshaft revolution then the value would stay

at ZERO (a completely dead cylinder will give a zero

reading)

As cylinder combustion is never perfect you will get

differing levels of effort being made for the same

cylinder - the greater that difference the higher the

smoothness value (a dodgy cylinder will give a higher

reading)

This example is of a healthy engine, lower values can

be seen, especially if you restart diagnostics when the

engine is running (usually the source of ‘my engine is

very smooth’ screenshots online!)

The screenshot above is from my 840ci, and so is the

one on the left, but before I fixed all sorts of vacuum

leaks.

The smoothness and Lambda screens showed that things

were not happy - my first plan was to swap coils around

(as it is easy to do) to see if cylinder 5 would perk up a

bit - but it didn’t, so I could discount ignition problems

It was the combination of Smoothness and Adaptations

that pointed towards a vacuum leak - using the

Smoothness values ruled out a dodgy ignition coil

That’s obviously not right at all! I trawled this from the

internet as an example. I would expect that the

Adaptations were at limits on this example as cylinder

5 is hardly firing consistently. Where a cylinder fires

inconsistently there will be unburnt fuel getting to the

Lambda sensor - the ECU will try and lean-out the

mixture but that will start to affect the other cylinders

This example is quite interesting as Bank 2 (cylinders 5

- 8) is badly affected whereas Bank 1 (cylinders 1 - 4)

look pretty happy - although the value of zero on

cylinder 2 probably means it’s not doing anything at

all. I would try and get cylinder 2 firing again - but my

best guess is that the catalytic converter is blocked on

Bank 2

MAF

THROTTL

E BODY

FUEL

INJECTOR

LAMBDA

SENSOR

ECU (Engine computer)

To catalytic converters

and exhaust system

Fresh air from air filter

That’s spot-on mate!

input 0.5 grams of air per rev

output 5ms injector duration

PLUS ADDITIVE ADAPTATION of 5ms

That’s basic adaptation at work - although the MAF measured only 0.5

grams of air per revolution the ADAPTATIONS have requested an

additional 5ms injector duration. It took quite a while for adaptations to

work themselves up to this point (if a large air-leak is introduced it may

take ten minutes at idle for adaptations to pull the mixture back

correctly). But, now the fuel/air mixture is correct (but only at this engine

speed and load) and all is jolly.

The EVIDENCE that something is wrong is that the Additive adaptations

will be quite noticeable - if the air-leak was large enough (like this

example is) then you will get an engine warning lamp lit and INPA will

show ‘adaptations at limit’. However, as long as the ECU has done its job

correctly there should be no misfire, the engine will be as smooth as

normal as the mixture is now correct again.

Additive and Multiplicative Adaptations

I’ve seen a couple of documents regarding when these two adaptation

types are modified - the blurb says:

•

Additive adaptations are made at IDLE, LOW LOAD and LOW TO

MID RANGE ENGINE SPEEDS

•

Multiplicative adaptations are made at NORMAL TO HIGHER

LOADS when at HIGHER ENGINE SPEEDS

But, my experience of the M62B44 shows that the Multiplicative

adaptations can be modified at idle when the Additive adaptations reach

their limits, so I’m not sure if the above information is perfectly true! But,

it is probably close enough for our purposes. As far as their effects on

engine performance is concerned, we can broadly say that:

•

The Additive adaptations have more effect at idle and only

slightly modify the cruising and acceleration performance.

•

The Multiplicative adaptations affect every aspect of engine

performance and that includes idle

Air leak at manifold,

PCV, gaskets, boots

etc

This is the correct temperature

when the M62 is fitted to an E31

- The E38 has a mapped

thermostat and at idle the

temperature should be 105C -

108C

The ECU has

calculated that

the ICV (Idle-

speed Control

Valve) needs to

open

sufficiently to

pass 24Kg/h -

this value

causes much

angst as it

often has the

(!) warning -

but this value

is within limits

Total air consumption

On the V8’s it should

be around 20Kg/h as

seen here. When the

engine is cold it is

normal to get a

warning (!) - the slider

scale was designed for

lesser engines!

This engine speed is

normal if A/C is ON -

if A/C is OFF it

should be around

550-600 RPM

Don’t bother diagnosing

problems if the running

voltage is less than 12.6V

The screen above is always a good place to start when things aren’t running

nicely - it gives a good indication of the basic sensors:

•

Battery Voltage - with the engine running we expect a voltage

between 12.6V to 14.6V. Anything below 12.6V means that something

is wrong with the alternator and low voltages will cause ignition

problems - so get that bit fixed first!

•

Engine Speed - On the M60, M62 and M62TUB the engine revs should

be 550 - 600 with the A/C OFF. If the A/C is switched ON and working

then the revs should increase to 700.

•

Air Intake Temperature - On the M60 engine this temperature sensor

is stuck on the RHS of the intake manifold, on the M62 engine it is

incorporated into the MAF - although on some models there is an

additional sensor on the air filter housing. The reported temperature

should be around the ambient temperature plus a few degrees. If the

temperature is mis-reported this will cause the adaptations to move

away from the ideal. Replace the MAF if the error is more than five or

six degrees out. However, on the N62 engines this value is often much

higher even on new MAF’s.

•

Coolant Temperature - This is the coolant temperature of the ENGINE.

On some models the radiator outlet temperature is also reported - we

are not interested in that when finding engine running problems. The

engine must be at running temperature for basic diagnostics. Although

the M62 engine is used across a few models, the coolant temperature is

lower when used in the E31 as this has a fixed 85C thermostat -

whereas the E38 and E39 have a temperature-mapped thermostat with

a passive opening temperature of 104C - at idle the reported

temperature would be around this value. When performing diagnostics

(unless you are looking for cold-start problems) it is imperative that the

engine reaches operating temperature - and if the engine fails to reach

the thermostat opening temperature then that could well be the source

of the engine performance problems

•

Needed Air I.S. Controller - On the M60 and M62 (not the TUB

version) the idle speed is controlled by an Idle-speed Control Valve

(ICV). The ECU calculates how much air this has to allow through it to

maintain the correct idle speed. This is the Needed air i.s. controller

value. Unfortunately the scale (just like that of the Total Air

Consumption slider) is too short for the mighty V8’s and although

everything is working perfectly you often (nearly always) get the (!)

warning next to it. Don’t panic, this is perfectly normal for the V8’s

•

Total Air Consumption HLM - This is the airflow that the MAF is

reporting. This often causes angst because a warning (!) is shown. But,

as long as this value is around 20Kg/h - 25Kg/h then everything is fine

for the V8’s. Just like the previous slider, the scale seems to have been

made too short for the larger engines. If diagnosing the car from cold

this value will be much higher and the warning (!) will be shown, again,

this is perfectly normal. The lack of a value here means that the MAF is

not connected or has failed. If the value is less than 18Kg/h when the

engine is hot that will indicate a vacuum leak, possibly around the inlet

manifold. Readings that are absolutely miles out usually indicate a

failed MAF

•

Throttle Potentiometer - this is the voltage reported from the throttle

position sensor which is fitted to the throttle body on the M60 and M62.

The M62TUB has a motorised throttle body (as does the N62) but this

value has been retained and is interpreted from the EML system rather

than directly from the throttle body. A voltage around 0.45V is expected

- plus or minus 0.1V. As the throttle is pressed this value will increase.

Due to the refresh rate of the diagnostic screen the value will move in a

jerky fashion - unless the value jumps backwards as the throttle is

increased then the potentiometer is probably OK.

On the M60 and M62 this value

is reported from the throttle

body potentiometer. This value

will move if the throttle is

opened - around 0.45V is

expected at idle

ANALOG VALUES 1

Primary and secondary engine

sensors

OPEN - LOOP

MIXTURE CONTROL

CLOSED - LOOP

MIXTURE

CONTROL

AIR LEAK

INTRODUCED

ADAPTATIONS

COMPENSATE

HOW ENGINE PROBLEMS AFFECT THE

READINGS

So, we know a lot more about how to use diagnostics and what each of the

screens can show us if we have an engine running problem. Obviously, if

you have a part of the engine that has completely died (such as a coil-pack)

then error codes are stored, and then repair is straightforward - and you

probably won’t be reading this. But, when parts sort of work but not

properly then these three screens will help us whittle the possibilities down.

Let’s have a quick look at problems and how they affect the readings.

•

Oil in the sparkplug wells (details and repair

information here)

This problem causes misfires on single cylinders rather than an overall

lumpiness of all 8 cylinders. If the coil completely failed we would find a

stored error code, and the ECU would inhibit the injector on that

cylinder to stop unburnt fuel getting to the catalytic converters. But

where it fires feebly and intermittently we can find evidence on both

Adaptations and Smoothness. We would expect to see an increase in

the smoothness value for that cylinder AND the Additive

Adaptations would be below zero as they compensated for the

partially combusted fuel

•

Failing catalytic converter (details and repair

information here)

Catalytic converters can fail in a way that blocks the flow of exhaust

gasses - either by melting or disintegrating. When they disintegrate

parts of the honeycomb can become detached and block the outlet from

the converter casing. In this situation the error happens quite quickly,

the car starts shaking and power is lost - but when the car is stopped

the errant bit of honeycomb of falls away from the outlet and all is good

when re-started. Where the honeycomb melts the exhaust flow is

reduced and so is engine power - but the evidence it leaves is quite

noticeable. This is one of the few errors that shows adaptations

completely different between the two Banks - one will be

positive, the other negative. The reason for this is that we only have

one MAF - and two banks. If the flow of gasses is inhibited on one bank

then that bank becomes richer, and the other leaner. It is also possible

to get knock sensor error codes when things get badly blocked.

•

Vacuum leaks around the manifold gaskets (details

and repair information here)

Manifold leaks can affect the smoothness of single cylinders and

adjacent cylinders along with an increase of Additive Adaptations.

This is due to the construction of the gaskets which serve two adjacent

cylinders and the design of the one-piece inlet manifold. The difference

between faulty coil packs and manifold leaks is that the latter increases

Additive Adaptations whereas a faulty coil pack (well, until it gives up

completely) reduces the adaptations.

•

Fuel pressure regulation problems (details

mentioned in this article)

The TIS always mentions fuel-rail pressure as the first thing that is

checked if you have engine running problems. But, as a general rule

they are pretty well behaved. But they do two things that really upset

the engine. They can leak internally and that pushes raw fuel directly

into the manifold via the vacuum pipe that runs between the FPR and

the PCV. That makes starting the engine difficult as the manifold is

flooded - but as far as diagnostics go it pushes the Additive

Adaptations negative and affects the Multiplicative Adaptations in

a much lesser way. If the pipe is removed it will be found to be wet

with fuel.

The pipe between the FPR and the PCV can be punctured and this

has the effect of increasing fuel-rail pressure to 3.5 Bar (instead of 3

Bar) and that will increase the amount of fuel that is added in all engine

ranges except full throttle. In this situation Additive Adaptations will

be very negative and Multiplicative Adaptations will be negative

to a lesser extent. A quick check for this problem is to pinch the

vacuum pipe and remove the FPR end - if the engine note does NOT

change the pipe is blocked, puncture or the FPR is faulty.

•

Vacuum leaks on external manifold parts (details

and repair information here)

These leaks can be around the throttle body, around the PCV gasket,

the vacuum lines to the brake booster and then capped off service ports

as mentioned in the article above. These leaks are easily compensated

for by adaptations and the clue is that Additive Adaptations are

positive, and Multiplicative Adaptations are positive to a much

lesser extent. Quite often the engine is perfectly happy until the

adaptations reach their limits.

•

MAF problems (discussed here)

The MAF always gets the blame - and the usual advice is to disconnect

it and see if the engine runs better - and it quite often does. With the

MAF disconnected the other sensors take the primary role - the throttle

potentiometer being the primary airflow sensor. But, if you want to do

this test correctly - switch off the car, ignition back ON, use diagnostics

to clear the engine adaptations, disconnect the MAF, switch the ignition

OFF and then re-start the car - how’s it running now? Using this

method will show if the default engine values give good performance,

and if they do the MAF is suspect. If the engine runs badly then the

fault is elsewhere.

Faulty MAF’s can cause all sorts of problems - but the signature of a

failed MAF is very high adaptations, quite often with Additive

Adaptations being negative and Multiplicative Adaptations being

positive. There is often a lack of performance, especially under harsh

acceleration where the Lambda sensor has no effect at all.

•

PCV failure (details and repair information here)

Not all PCV failures cause smoke, some just let lots of un-metered air

in (they usually make a whistling noise at the same time). Sometimes

they just let a small amount of air in and these leaks are easily

compensated for by adaptations and the clue is that Additive

Adaptations are positive, and Multiplicative Adaptations are

positive to a much lesser extent. Quite often the engine is perfectly

happy until the adaptations reach their limits. However, they usually

get worse to a point where you get several misfires, especially on a

cold start.

SEARCH MEEKNET