TIMM'S PERFORMANCE CHIPPING

THE E31

840i, E32

730i AND 740i, AND EARLY E38's WITH THE M60 V8 ENGINE

These instructions are suitable for

fitting new software (Chip) in BMW M60 V8's that are controlled by the Motronic 0261 200 404

or 0261 203 484 DME's. Although other DME's are similar there may

be slight differences, some older DME's have a single PCB construction, the DME

we are working on has two PCB's.

I fitted a BBR StarChip, this was around £150. They can be found here:

http://www.morego.co.uk/bbr-gti/StarChip.php

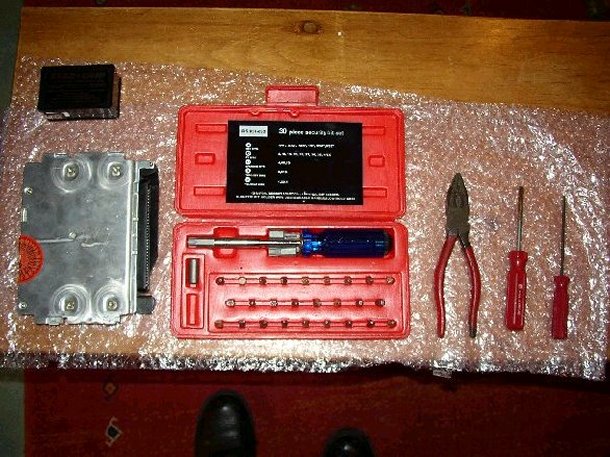

To start with you will need a few tools, a Torx set (although you really only

need two sized bits), a pair of pliers and a couple of flat-bladed screwdrivers.

Find somewhere clean to work, a plain wooden table is suitable as this will

discharge any static, don't try and do this on a plastic table!

Tools:

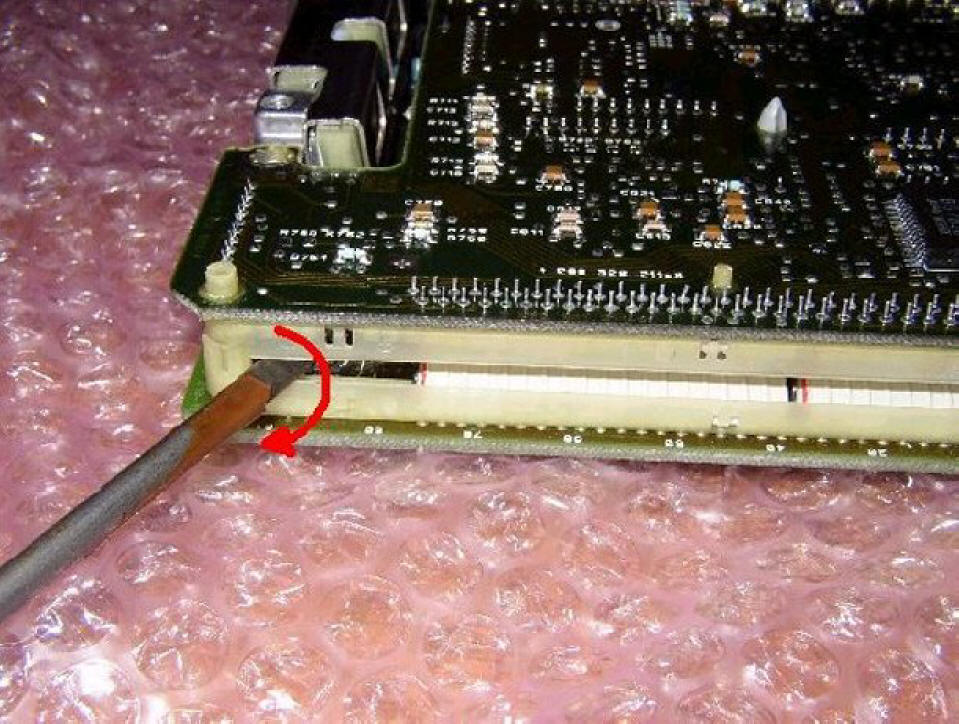

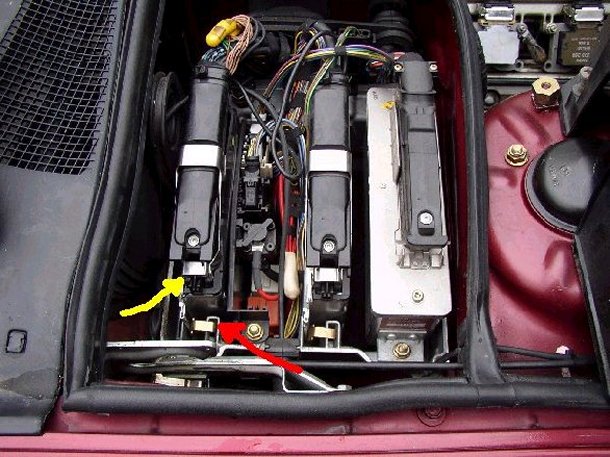

Here is where the DME lives on the V8, nearest to the windscreen. Before you

start I recommend that you disconnect the battery and leave it sitting with the

battery disconnected for 10 minutes. To remove the connector from the DME lift

the catch (YELLOW arrow), and pull the connector away from the front as shown

here. The connector hinges from the back, don't bend the wires too much but get

the connector out of the way of the metal clips. There are two metal clips (RED

arrow), these are just pulled up using the pliers, they are quite stiff so make

sure you don't mangle anything on the way out. The DME can then be pushed

towards the front of the car and then lifted out, mine was a bit constrained by

the electronics to the right in this picture but came out all the same....

With the DME safely out undo the upper screws with the Torx drive.....

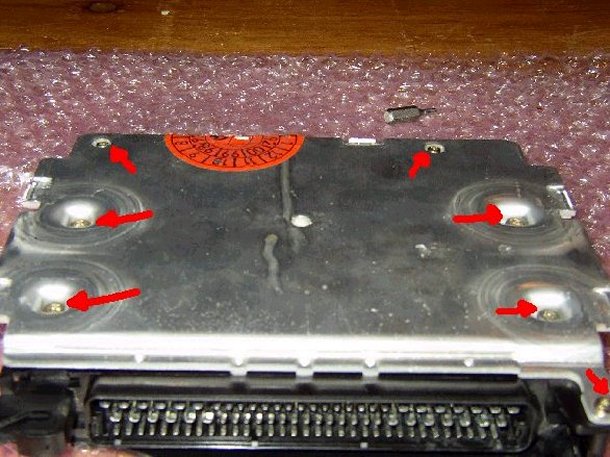

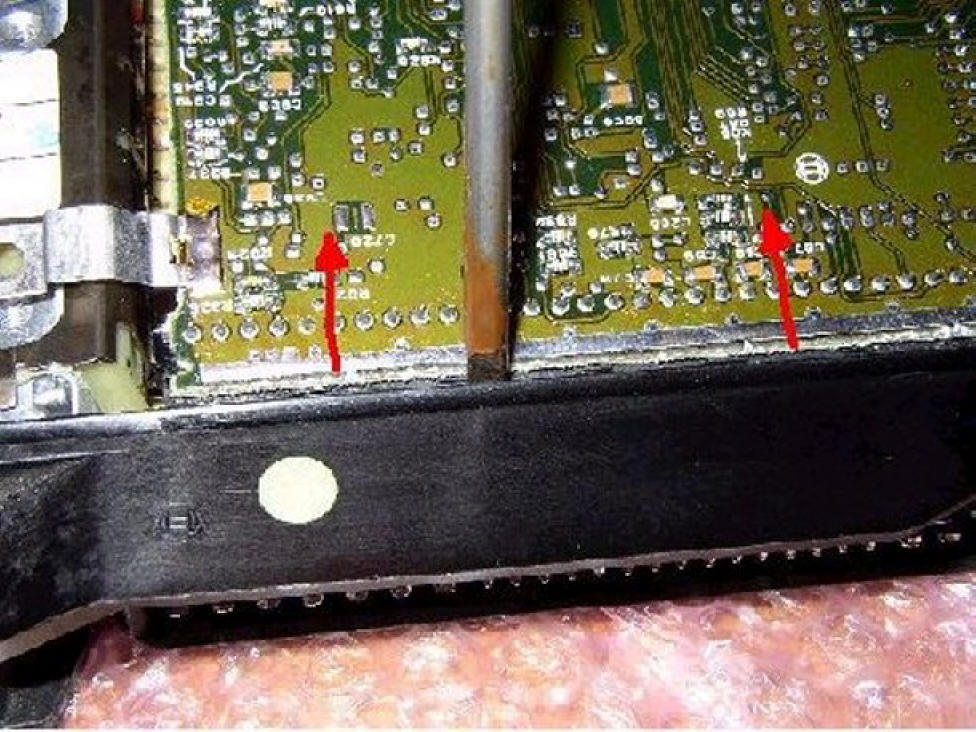

The lower half is held by four large Torx bolts and three small ones, undo them

all....

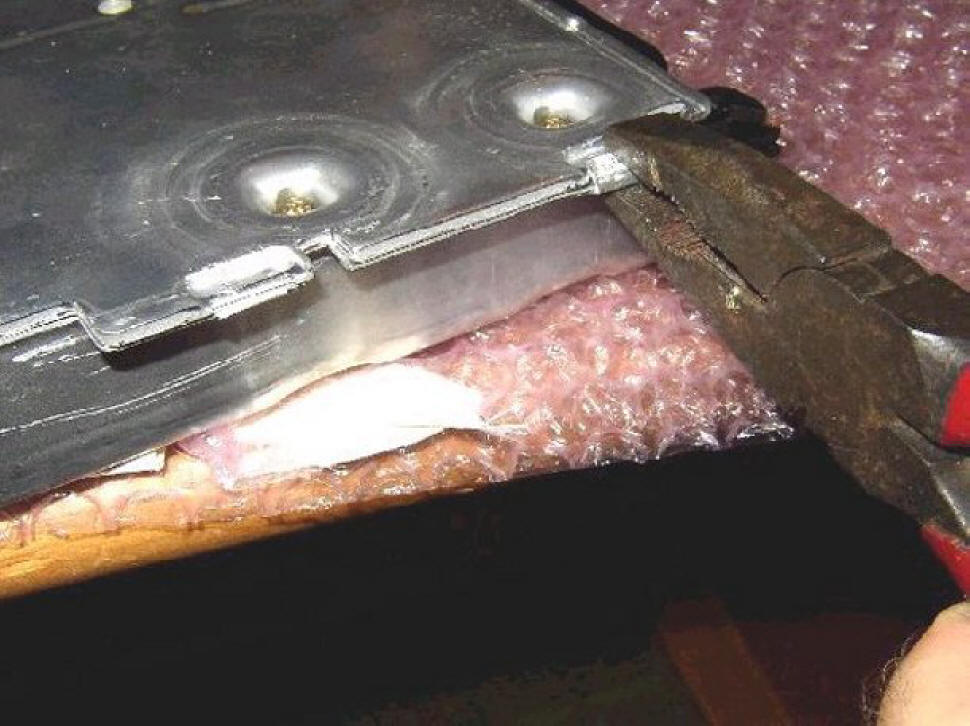

The case is held together by a few bent-metal clips, if this is the first time

the DME has come apart they will bend.....if this has been done before (and will

have been if the car was serviced at a main dealer and the software upgrades

have been done) then the metal clips will drop off....no great loss.....

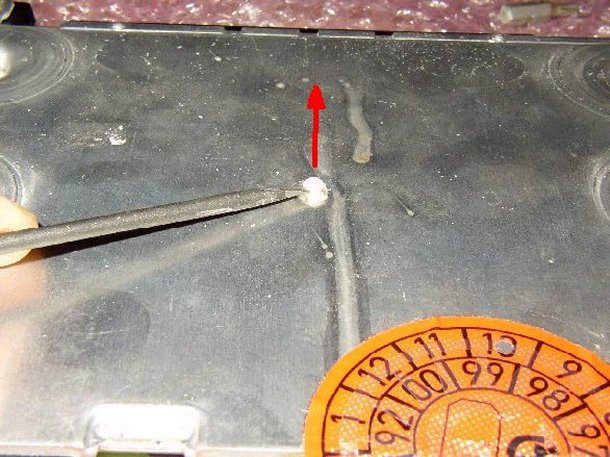

Lift out the centre of the plastic pillar support, it will come all the way

out......

With the covers now removed undo the Torx bolt securing the PCB....

Then press together the PCB securing clip as shown here, slightly lift the PCB

so that the clip is left unsecured.....

Next, lever apart the rear PCB pillars so that they are disconnected.....

With the rear pillars disconnected and the PCB clip squashed lift the back of

the PCB and straighten out the wiring, it doesn't have to be completely straight

but similar to that shown here.....I failed to do this when I did mine and took

ages to work out that the wires needed to be straight before the PCB would come

out!....

Give the connector clip a quick tweak (mine only had one on one side but I

expect there to be one each side)....they should remain in the open position due

to the tilt of the PCB.....

The PCB can now be moved backwards with a bit of a tweak, note that the top row

of connections are now almost touching the middle row, this is how it should

be......

Now the top PCB can be tilted backwards away from the connector, the top row of

connections are part of the top PCB!......

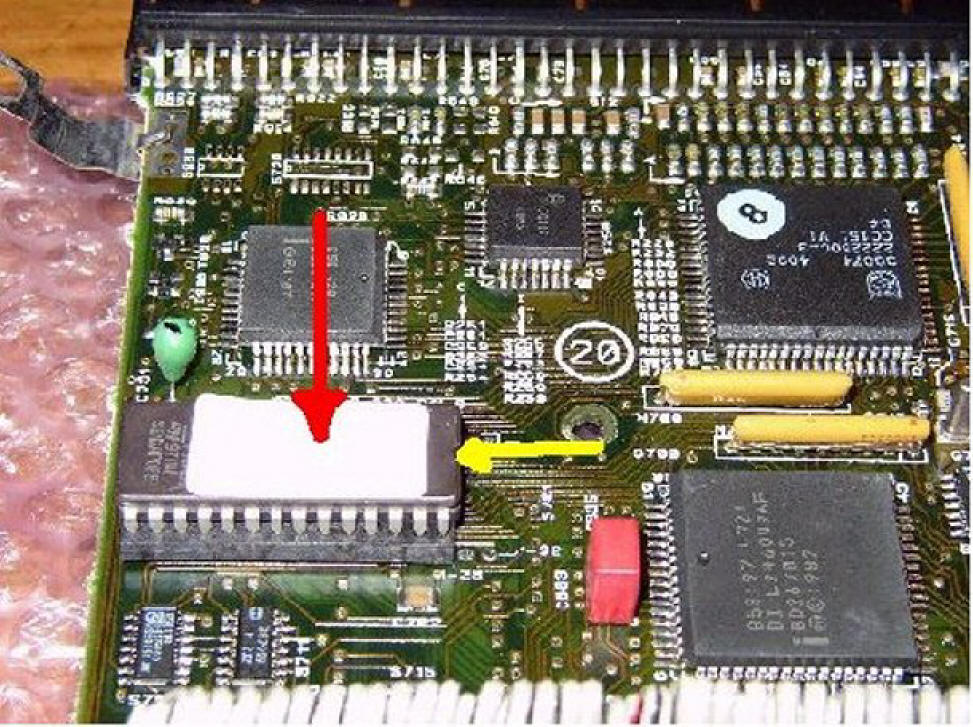

Here's the EEPROM that needs to be changed. I seem to have forgotten to take a

picture of the cover that was fitted to it. This plastic cover clips over the

EEPROM and helps to secure it in place. The plastic cover has two slots on the

long sides, you can fit a small flat-bladed screwdriver in them and give them a

quick tweak outwards to lift the lower edge away from the EEPROM carrier. I just

used my fingers to remove the cover, it is quite thin and flimsy but didn't fall

apart.....Note that the old and new EEPROM has an indentation at one end as

shown by the yellow arrow, make sure the new one goes in the same way around....

Lever out the old EEPROM using a small flat-bladed screwdriver, a little bit at

a time from each end. Wiggle the screwdriver under the EEPROM as you lift it up,

don't rush it and don't bend all the legs. The EEPROM should effectively be

lifted straight upwards, too much of an angle and the legs may be damaged....you

never know if you may need it again. Once the EEPROM is out stick it on the

anti-static foam that is supplied with the new EEPROM.....

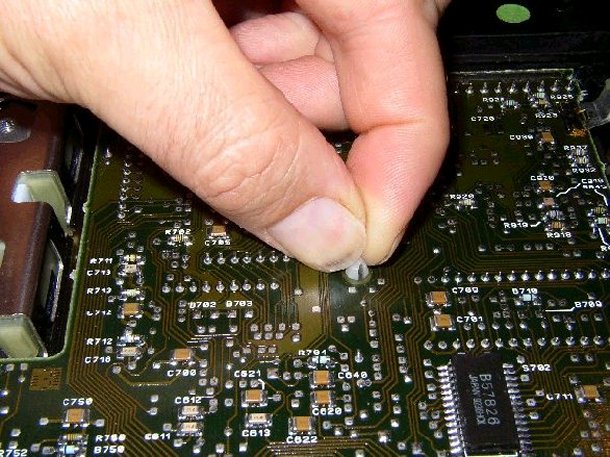

Remove the new EEPROM from the anti-static foam and ensure that you touch the

DME with your other hand before fitting it in the socket, this will ensure that

you, the new EEPROM and the DME are all at the same potential. Carefully align

one of the long edges so that the EEPROM legs are all above the sockets and then

lower the other side towards the socket, as long as the EEPROM has been properly

prepared (and the Star Chip was) the legs should align perfectly. When all the

legs are above the socket and are correctly aligned carefully press the EEPROM

into its socket. Make sure that you only apply a little force, if too much

resistance is felt then one of the legs are not correctly aligned and will bend.

If this happens remove the EEPROM again using the previous instructions and

straighten the leg(s) using a plain edged pair of pliers, the legs will

withstand quite a few bendings, they are not brittle.Make sure you got the new

EEPROM the right way around (as shown in previous post) and then push the

plastic cover back on the EEPROM. You will have to slightly prise the cover to

get it over the EEPROM and its carrier.....

Right, time to stick it all back together.....Carefully bend the top PCB over

and slide the top PCB connections into the front connector.Poke the wires at the

back towards the centre of the unit, this will bring the upper PCB down.Ensure

that the front of the top PCB is within the connector and pushed forward, now

squash the PCB pillars together until they click.Ensure that the PCB securing

clip in the centre of the PCB has popped through the hole, push the PCB onto it

and ensure that the clip has opened and secured the top PCB.Refit the Torx bolt

that secures the top PCB in place......

Refit the Torx screws to the top and bottom covers. Squash the (remaining) metal

clips over the case.....

Refit the DME to the Ebox, ensure that the metal clips are correctly aligned

with the DME as you push them back into place using a pair of pliers, it is

possible to miss the edge of the DME. The clips serve to press the DME against

the chassis of the Ebox and are required to effectively heat-sink the DME...don't

miss the clips off!

The connector now needs to be refitted. This took me ages until I realised that

the connector has to be at quite an acute angle so that the rear securing tab

slides into the receptacle before the front of the connector can be lowered.

Don't apply excessive force, it should connect quite easily. Lower the metal

securing clip into place as shown in this picture.....

Fit the lid back on the Ebox (it needs the lid on for the air circulation to

work properly), reconnect the battery. Find out you've forgotten the radio

code....swear a bit and start up the engine.........

WHAT TO EXPECT

The new software will not know what it's up to to start with, the engine should

slowly regain its idle speed of around 500RPM with the A/C off or 600RPM with it

on. It may stall when you put the car into gear (mine did), but re-started OK

and didn't stall again. Drive the car in differing conditions (driving like a

granny, giving it a good thrash) and the DME will learn the best settings.

I whizzed up the A3 after a bit of back-lane driving and the car failed to shift out of 4th gear at 85MPH in 'E' mode. This only happened on my first blast and all worked correctly after going around a roundabout.Gear changes are now slightly delayed to where they were before, it makes the car a lot livelier, 'S' mode is very quick with changes being made right on the red line. Want to overtake someone when in 'E' mode?...don't bother sticking it in 'S' just stick the boot down for amazingly quick change down a few cogs and away you go.

MPG is

indicated to be about 3MPG better (now showing 30MPG for a A road- motorway trip

as opposed to 27MPG before, however, I don't believe it).I don't recommend doing

this without disconnecting the battery. The DME has an unswitched live feed, you

will only need to drop the connector on a metal surface for upsetting

fireworks.All in all worth doing.Just don't forget to have a note of the radio

code before you start.......

All done, time for a cup of tea......

P.S. If you need any help just contact me via the Forum......Timm....

P.P.S This is an extract from the post I made in the old E32 Forum. I've driven

about 40,000 miles since the chip was fitted and the MPG increase WAS real and I

still get around 31MPG for the round trip from Hampshire to Bristol and back

(32.4 on my last trip on Monday).......