.

.

.

TIMM'S BMW E32 7-SERIES - THE 10 MOST COMMON PROBLEMS

The E32 is an excellent car, but even the flagship of the BMW range has a few weak spots. From my own experience, that of The 7 Series

Register and the percentage hits on this website a definitive list can be made. Most of the problems exist in all models in the range, some only

for the V8 models. In 2018 the E32’s are disappearing quickly, and one of the major problems (especially in the UK) is rust, a problem with all

cars, and the E32 suffers no more than than any other BMW

The following list is in order of highest to lowest chance of problems

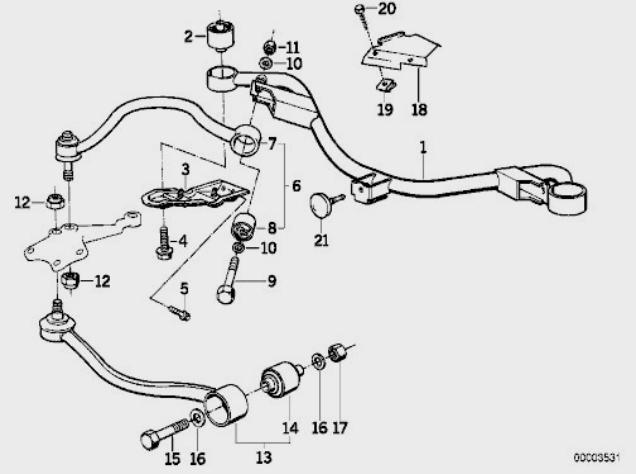

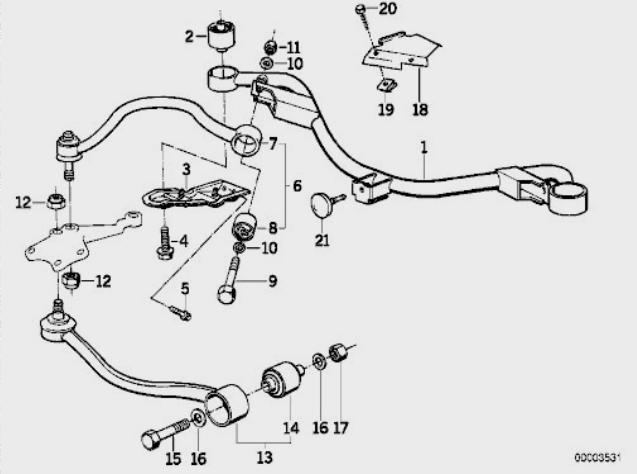

1. The Dreaded Shimmy

Both the E32 and the E38 7-Series can suffer from the dreaded 'shimmy'. This is wheel-wobble that usually first shows itself under braking, for

instance, when coming off a motorway intersection and braking from high speed. The wobble can be felt through the steering-wheel but it

usually disappears as the car speed reduces.

Sometimes this is all you ever get, but more usually you will start to get wobble as the car is accelerated through 50 - 60MPH. The more you

drive the car the worse it will get. The wobble is quite often accompanied by tram lining and a general feeling of imprecision from the steering

in general.

The shimmies are often an indication of general wear in the steering system and suspension, the BMW E32 has a great deal of weight over the

front wheels, especially when braking. It also seems to have a resonant frequency that occurs between 50 and 60 MPH, if there is any

weakness it is at this speed where the problems will occur.

The shimmies can be repaired, often very simply. Click here for repair information

2. Cooling system

This is another problem that the E32 shares with the E38. There are two areas of the cooling system that are particularly weak:

Radiator. The E32 radiators have a plastic body, they break around the Top Hose connection. The Top Hose fitted to the radiator with the aid

of a Jubilee-clip. The usual problem is that the plastic pipe that the hose is connected to cracks under the Jubilee-clip and this causes a small

weep around the hose that is difficult to trace. The usual evidence is white marks down the side of the radiator. The only repair is the

replacement of the radiator.

Viscous Fan. The Viscous Fan is mounted on the water pump shaft and is driven by the main belt from the crankshaft pulley. The assembly

consists of a temperature-dependant viscous-clutch driven from the pump shaft that drives a large plastic fan. When the clutch is cold the fan

idles and can be stopped with a rolled-up newspaper (the usual test), once the clutch is hot the fan is driven with a much greater torque and

produces a great deal of air-flow. The usual problem is that the clutch fails and the fan cannot produce enough air-flow. The fault will show

itself when the car is stationary when it will rapidly overheat. The temperature-rise is usually halted by the the auxiliary fan (A/C fan) which

will operate independently to the A/C system when required. Once the car is moving the temperature starts to drop. A more unusual problem

is that the clutch seizes, this is first noticed by large whooshing noises when the car is revved-up. Replace the viscous coupling immediately if

this happens as the fan will disintegrate and this can cause all sorts of damage including big holes in the bonnet! Replacement of the Viscous

Fan is pretty simple and is covered here (E38 shown E32 similar)

3. Air Conditioning. The A/C system tends to slowly leak gas, fortunately re-gassing gets things going again successfully. Re-gassing is

covered here.

4. PCV Valve Failure. The V8 E32's suffer from PCV valve failure when they reach a certain age. The PCV valve consists of a diaphragm

fitted to a housing that is fitted to the rear of the inlet manifold and when this is damaged it can cause erratic idling and excess smoke. Often

mistaken for Nikasil problems in the early models, the repair is pretty straight-forward but does require a bit of patience especially when

trying to get the Torx bolts out of the bellows assembly. The repair is covered here.

5. Trans Prog Error. If there is one fault that makes you sweat, this is it! You get the message of doom on the OBC and the gearbox locks

itself in 3rd on the 4-speed boxes or 4th on the 5-speed boxes. You immediately realise that the cost of a replacement box is more than the

car is worth and aim the car at something that will produce a terminal insurance claim. However, don't panic, in 9 cases out of 10 the problem

is easy to fix. Here is the most likely candidates:

Battery Voltage Too Low. The E32 hates having a low battery voltage and one of the first things that gives up is the gearbox. Although the

EGS (control unit) keeps running, the 12V solenoids in the gearbox don't, the EGS sees this as a failure of the valve-body and gives up. Low

battery voltage is often due to short trips, failing battery or a faulty alternator. Disconnect the battery, replace if needed or give it an

overnight charge and have another go, hopefully the problem will not return.

S.E.M Switch. This is the Sports, Economy, Manual switch next to the shifter (marked SE* on the V8's). Although it is a simple momentary

switch it can intermittently make contact when in the rest position, or select 'S' and 'M' at the same time. This causes an error in the EGS.

The switch can be removed and cleaned or (for emergency use) you can replace it with the sunroof switch!

Shifter Selector Switch. The selector switch is a multi-pole, multi-throw unit and produces a switch pattern (akin to binary) to the EGS.

Problems occur when the contacts get dirty and the one of the switch elements fails to make contact. The switch pattern sent to the EGS is

incorrect and the EGS flags a Trans Prog Error. The shifter selector switch can be removed and cleaned with contact cleaner quite successfully.

Low ATF Level-Filter Blocked. Pretty obvious one this, however, the box usually starts slipping when cornering first. Still, when all else has

failed it is worth replacing the filter and getting the oil changed.

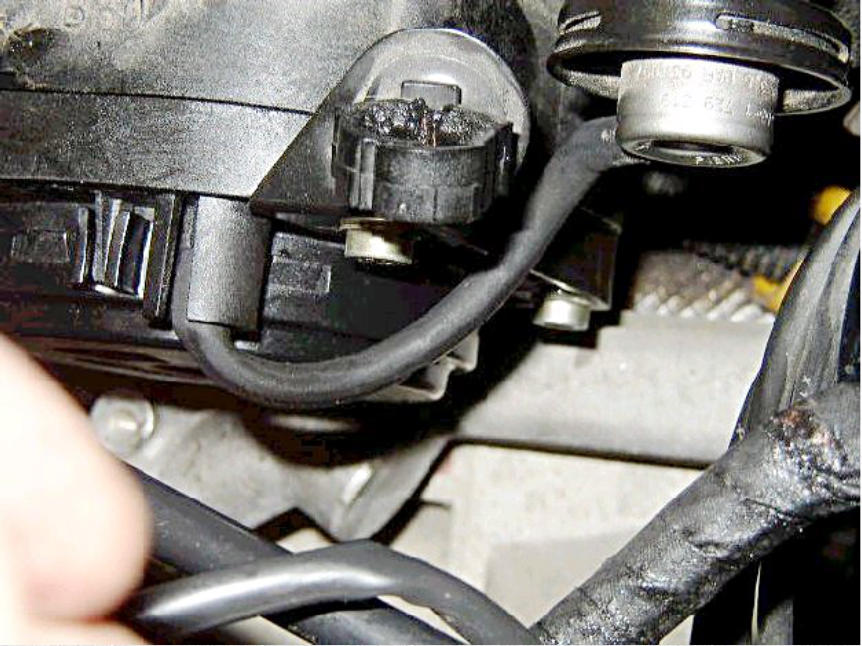

6. Rocker-Cover Leaks. A small oil leak isn't too much of a problem unless the oil fills up the spark-plug holes! Unfortunately this is exactly

what happens on the V8 models. The engines use coil-over-plug ignition coils with short HT-stubs, and it is these stubs that are damaged by

the oil. Once the HT-stubs are damaged the engine will start to misfire. The repair is covered here.

7. Noisy Tappets. There are two different problems here. The M60-engined cars get noisy tappets that come and go, this is not a problem

and is covered here.

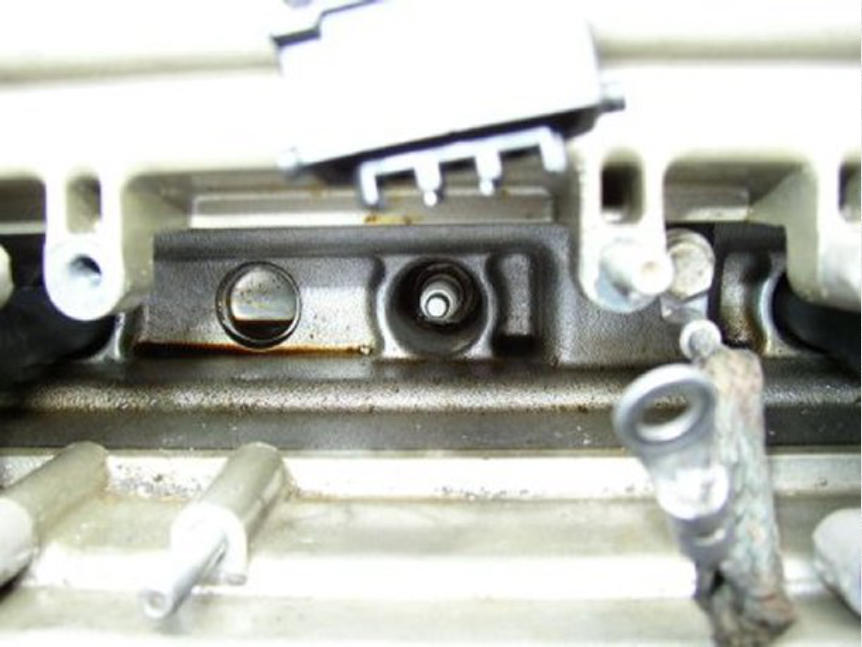

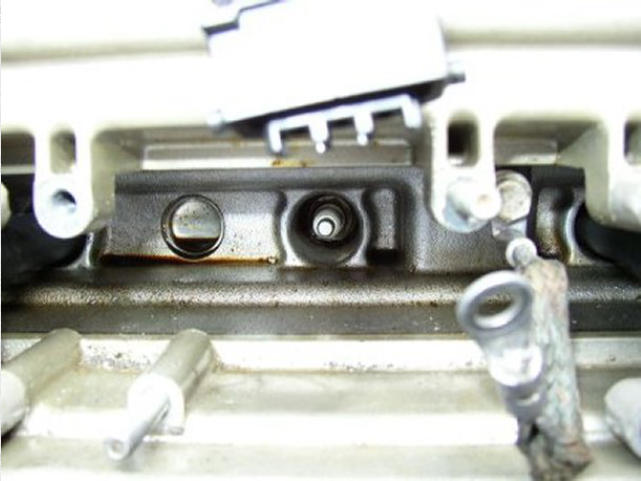

The M30-engined cars get noisy tappets due to cam wear due to a lack of lubrication. The lack of lubrication is due to the loosening of hollow

bolts known as 'Banjo Bolts'. These bolts direct oil from the upper oil gallery to the cam spray bar. The problem is that the bolts cannot be

tightened too much as they will be damaged due to the hollow construction and they eventually come loose and this starves the front lobes of

oil. The bolts should be locked with thread-lock but even this gives up, especially when the bolts are 'checked for tightness'.

Banjo Bolts can be purchased with wire-holes so the bolts can be wired in position, this is the preferred method as it is impossible to remove

all traces of the oil from the gallery which is required to use thread-lock. Unfortunately, once the tappets get noisy the cam is starting to wear

quickly, and if left too long the rocker will seize and then snap in half, the wise money is on replacing the Banjo Bolts with the wired types

before this becomes a problem.

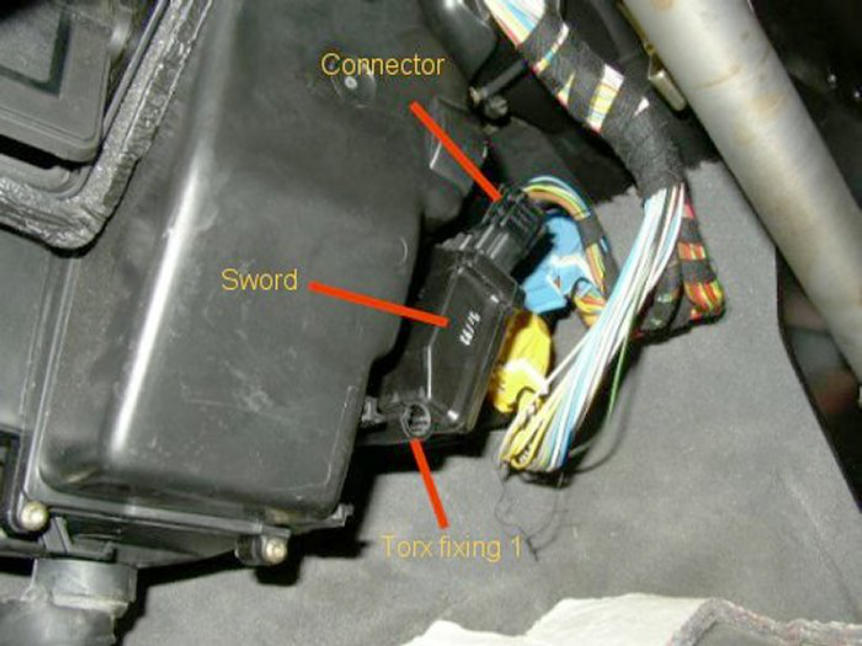

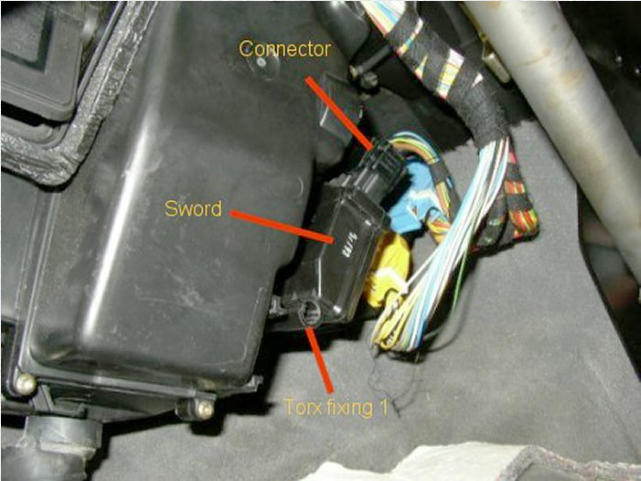

8. Blower Final Stage (Sword) Failure. Another classic problem that causes much angst. The 'Sword' is used to control the speed of the

ventilation system blower fan. Rather than just having a couple of ballast resistors as was seen in lesser models, the E32 has a continuously-

adjustable speed control. This is achieved with a number of Field-Effect-Transistors (FET's) mounted on a metal heatsink that vaguely

resembles a sword. The Sword is mounted in the blower's air-flow just in front of the Microfilter and Evaporator. When the FET's fail they

usually fail short-circuit which means that the fan runs continuously at full-speed. If the solder-joints fail the fan fails to run unless the fan-

speed is set to full, this is because a relay is used across the FET's at full-speed.

Failure of the sword is usually due to a blocked Microfilter, the driver increases the fan-speed to compensate but the airflow across the FET's is

insufficient to cool them. They get hot enough to melt the solder connections which eventually leads to 'dry' joints, quite often the FET's give

up altogether. The FET's can be replaced with a little soldering skill. Removal of the sword and replacing the Microfilter is covered here

9. Lighting Problems-False OBC Messages. There are a number of faults covered here all lumped under one heading but all concerning the

external lighting. The E32 lighting system changed quite considerably across the model years and some faults are confined to certain years:

False 'Bulb Failure' Messages. If you have a single warning message (usually brake light or rear side-light warning) and the bulb is

definitely working the most likely cause is corrosion on the bulb-contacts. Clean the contacts with fine emery-cloth and squirt some contact-

cleaner on the contacts....that usually cures the fault.

If you get multiple warnings on the later V8 models, side lights, rear lights, brake lights etc. then the fault is usually due to the headlight-aim

motors. These get electrically noisy and the noise confuses the Check-Control-Module (CCM). The simple repair is to get the headlights aimed

correctly and then remove the connector to the motors.

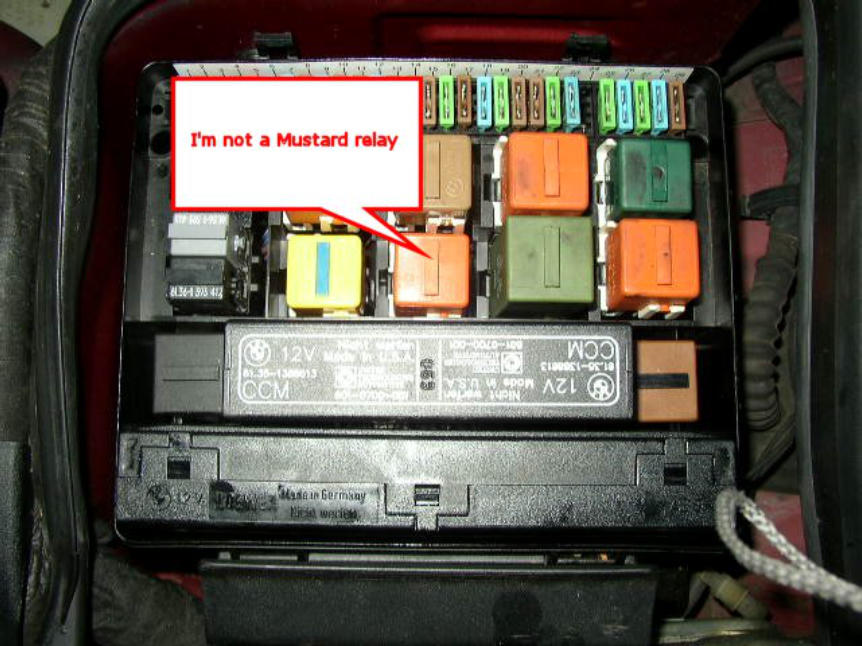

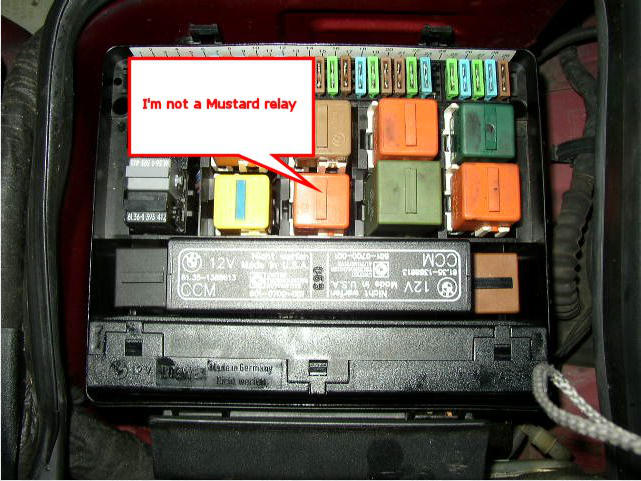

Intermittent Rear/Brake lights. If you have rear lights that are intermittent the most likely cause is the famous 'Mustard Relay' which was

present on early models. The picture below shows where it isn't on the later models as the Mustard Relay was replaced by electronics in the

LKM (Lamp Control Module). The relay can be taken apart and re-soldered.

Intermittent Headlights. On the early models this fault is again due to fatigued solder-joints but this time on the LKM. The early LKM's had

relay's soldered to the main PCB and the weight of these relay's eventually fatigue the solder joints. The LKM can be taken apart and the

solder joints remade.

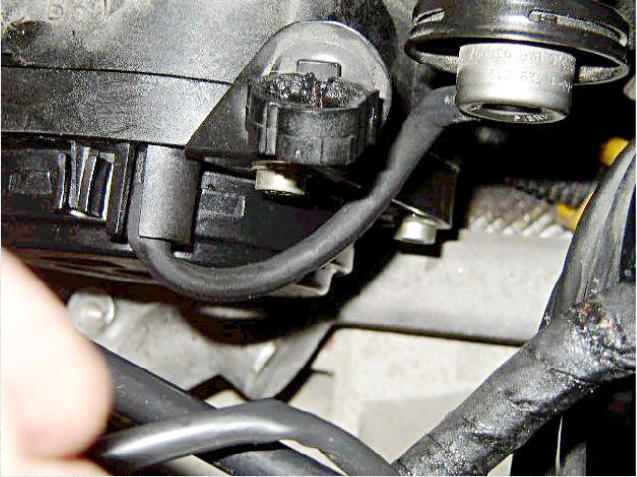

10. External Temperature -37F. Another trivial fault but still annoying, this is due to either the probe (shown below at the top LHS of the

RHS fog light cavity), or the connection into the loom which is found behind the cavity.

.

.

.

.

TIMM'S BMW E32 7-SERIES - THE 10 MOST

COMMON PROBLEMS

The E32 is an excellent car, but even the flagship of the BMW range has a

few weak spots. From my own experience, that of The 7 Series Register

and the percentage hits on this website a definitive list can be made. Most

of the problems exist in all models in the range, some only for the V8

models. In 2018 the E32’s are disappearing quickly, and one of the major

problems (especially in the UK) is rust, a problem with all cars, and the

E32 suffers no more than than any other BMW

The following list is in order of highest to lowest chance of problems

1. The Dreaded Shimmy

Both the E32 and the E38 7-Series can suffer from the dreaded 'shimmy'.

This is wheel-wobble that usually first shows itself under braking, for

instance, when coming off a motorway intersection and braking from high

speed. The wobble can be felt through the steering-wheel but it usually

disappears as the car speed reduces.

Sometimes this is all you ever get, but more usually you will start to get

wobble as the car is accelerated through 50 - 60MPH. The more you drive

the car the worse it will get. The wobble is quite often accompanied by

tram lining and a general feeling of imprecision from the steering in

general.

The shimmies are often an indication of general wear in the steering

system and suspension, the BMW E32 has a great deal of weight over the

front wheels, especially when braking. It also seems to have a resonant

frequency that occurs between 50 and 60 MPH, if there is any weakness it

is at this speed where the problems will occur.

The shimmies can be repaired, often very simply. Click here for repair

information

2. Cooling system

This is another problem that the E32 shares with the E38. There are two

areas of the cooling system that are particularly weak:

Radiator. The E32 radiators have a plastic body, they break around the

Top Hose connection. The Top Hose fitted to the radiator with the aid of a

Jubilee-clip. The usual problem is that the plastic pipe that the hose is

connected to cracks under the Jubilee-clip and this causes a small weep

around the hose that is difficult to trace. The usual evidence is white

marks down the side of the radiator. The only repair is the replacement of

the radiator.

Viscous Fan. The Viscous Fan is mounted on the water pump shaft and is

driven by the main belt from the crankshaft pulley. The assembly consists

of a temperature-dependant viscous-clutch driven from the pump shaft

that drives a large plastic fan. When the clutch is cold the fan idles and can

be stopped with a rolled-up newspaper (the usual test), once the clutch is

hot the fan is driven with a much greater torque and produces a great deal

of air-flow. The usual problem is that the clutch fails and the fan cannot

produce enough air-flow. The fault will show itself when the car is

stationary when it will rapidly overheat. The temperature-rise is usually

halted by the the auxiliary fan (A/C fan) which will operate independently

to the A/C system when required. Once the car is moving the temperature

starts to drop. A more unusual problem is that the clutch seizes, this is

first noticed by large whooshing noises when the car is revved-up. Replace

the viscous coupling immediately if this happens as the fan will

disintegrate and this can cause all sorts of damage including big holes in

the bonnet! Replacement of the Viscous Fan is pretty simple and is covered

here (E38 shown E32 similar)

3. Air Conditioning. The A/C system tends to slowly leak gas, fortunately

re-gassing gets things going again successfully. Re-gassing is covered

here.

4. PCV Valve Failure. The V8 E32's suffer from PCV valve failure when

they reach a certain age. The PCV valve consists of a diaphragm fitted to

a housing that is fitted to the rear of the inlet manifold and when this is

damaged it can cause erratic idling and excess smoke. Often mistaken

for Nikasil problems in the early models, the repair is pretty straight-

forward but does require a bit of patience especially when trying to get

the Torx bolts out of the bellows assembly. The repair is covered here.

5. Trans Prog Error. If there is one fault that makes you sweat, this is it!

You get the message of doom on the OBC and the gearbox locks itself in

3rd on the 4-speed boxes or 4th on the 5-speed boxes. You immediately

realise that the cost of a replacement box is more than the car is worth

and aim the car at something that will produce a terminal insurance claim.

However, don't panic, in 9 cases out of 10 the problem is easy to fix. Here

is the most likely candidates:

Battery Voltage Too Low. The E32 hates having a low battery voltage

and one of the first things that gives up is the gearbox. Although the EGS

(control unit) keeps running, the 12V solenoids in the gearbox don't, the

EGS sees this as a failure of the valve-body and gives up. Low battery

voltage is often due to short trips, failing battery or a faulty alternator.

Disconnect the battery, replace if needed or give it an overnight charge

and have another go, hopefully the problem will not return.

S.E.M Switch. This is the Sports, Economy, Manual switch next to the

shifter (marked SE* on the V8's). Although it is a simple momentary

switch it can intermittently make contact when in the rest position, or

select 'S' and 'M' at the same time. This causes an error in the EGS. The

switch can be removed and cleaned or (for emergency use) you can

replace it with the sunroof switch!

Shifter Selector Switch. The selector switch is a multi-pole, multi-throw

unit and produces a switch pattern (akin to binary) to the EGS. Problems

occur when the contacts get dirty and the one of the switch elements fails

to make contact. The switch pattern sent to the EGS is incorrect and the

EGS flags a Trans Prog Error. The shifter selector switch can be removed

and cleaned with contact cleaner quite successfully.

Low ATF Level-Filter Blocked. Pretty obvious one this, however, the box

usually starts slipping when cornering first. Still, when all else has failed it

is worth replacing the filter and getting the oil changed.

6. Rocker-Cover Leaks. A small oil leak isn't too much of a problem

unless the oil fills up the spark-plug holes! Unfortunately this is exactly

what happens on the V8 models. The engines use coil-over-plug ignition

coils with short HT-stubs, and it is these stubs that are damaged by the

oil. Once the HT-stubs are damaged the engine will start to misfire. The

repair is covered here.

7. Noisy Tappets. There are two different problems here. The M60-

engined cars get noisy tappets that come and go, this is not a problem and

is covered here.

The M30-engined cars get noisy tappets due to cam wear due to a lack of

lubrication. The lack of lubrication is due to the loosening of hollow bolts

known as 'Banjo Bolts'. These bolts direct oil from the upper oil gallery to

the cam spray bar. The problem is that the bolts cannot be tightened too

much as they will be damaged due to the hollow construction and they

eventually come loose and this starves the front lobes of oil. The bolts

should be locked with thread-lock but even this gives up, especially when

the bolts are 'checked for tightness'.

Banjo Bolts can be purchased with wire-holes so the bolts can be wired in

position, this is the preferred method as it is impossible to remove all

traces of the oil from the gallery which is required to use thread-lock.

Unfortunately, once the tappets get noisy the cam is starting to wear

quickly, and if left too long the rocker will seize and then snap in half, the

wise money is on replacing the Banjo Bolts with the wired types before this

becomes a problem.

8. Blower Final Stage (Sword) Failure. Another classic problem that

causes much angst. The 'Sword' is used to control the speed of the

ventilation system blower fan. Rather than just having a couple of ballast

resistors as was seen in lesser models, the E32 has a continuously-

adjustable speed control. This is achieved with a number of Field-Effect-

Transistors (FET's) mounted on a metal heatsink that vaguely resembles a

sword. The Sword is mounted in the blower's air-flow just in front of the

Microfilter and Evaporator. When the FET's fail they usually fail short-

circuit which means that the fan runs continuously at full-speed. If the

solder-joints fail the fan fails to run unless the fan-speed is set to full, this

is because a relay is used across the FET's at full-speed.

Failure of the sword is usually due to a blocked Microfilter, the driver

increases the fan-speed to compensate but the airflow across the FET's is

insufficient to cool them. They get hot enough to melt the solder

connections which eventually leads to 'dry' joints, quite often the FET's

give up altogether. The FET's can be replaced with a little soldering skill.

Removal of the sword and replacing the Microfilter is covered here

9. Lighting Problems-False OBC Messages. There are a number of

faults covered here all lumped under one heading but all concerning the

external lighting. The E32 lighting system changed quite considerably

across the model years and some faults are confined to certain years:

False 'Bulb Failure' Messages. If you have a single warning message

(usually brake light or rear side-light warning) and the bulb is definitely

working the most likely cause is corrosion on the bulb-contacts. Clean the

contacts with fine emery-cloth and squirt some contact-cleaner on the

contacts....that usually cures the fault.

If you get multiple warnings on the later V8 models, side lights, rear

lights, brake lights etc. then the fault is usually due to the headlight-aim

motors. These get electrically noisy and the noise confuses the Check-

Control-Module (CCM). The simple repair is to get the headlights aimed

correctly and then remove the connector to the motors.

Intermittent Rear/Brake lights. If you have rear lights that are

intermittent the most likely cause is the famous 'Mustard Relay' which was

present on early models. The picture below shows where it isn't on the

later models as the Mustard Relay was replaced by electronics in the LKM

(Lamp Control Module). The relay can be taken apart and re-soldered.

Intermittent Headlights. On the early models this fault is again due to

fatigued solder-joints but this time on the LKM. The early LKM's had

relay's soldered to the main PCB and the weight of these relay's eventually

fatigue the solder joints. The LKM can be taken apart and the solder joints

remade.

10. External Temperature -37F. Another trivial fault but still annoying,

this is due to either the probe (shown below at the top LHS of the RHS fog

light cavity), or the connection into the loom which is found behind the

cavity.