BMW E38

Timm's The BMW M60 M62 M62TUB and N62TUB Engine

Crankcase Ventilation - OSV and PCV

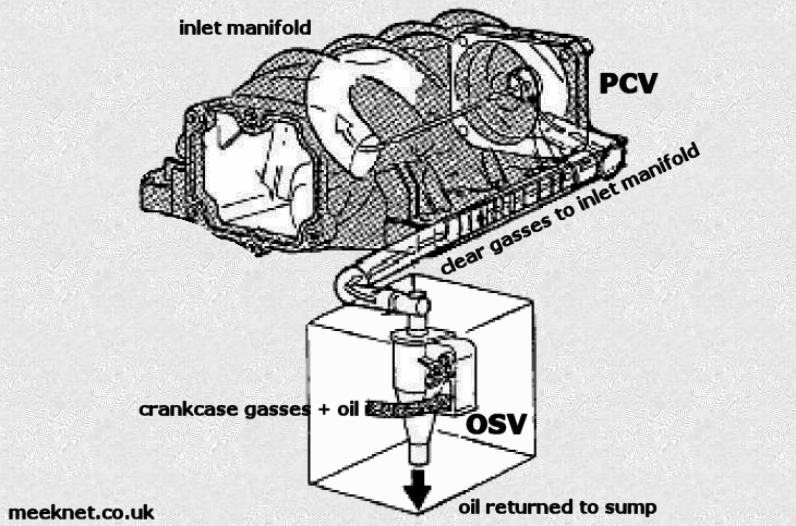

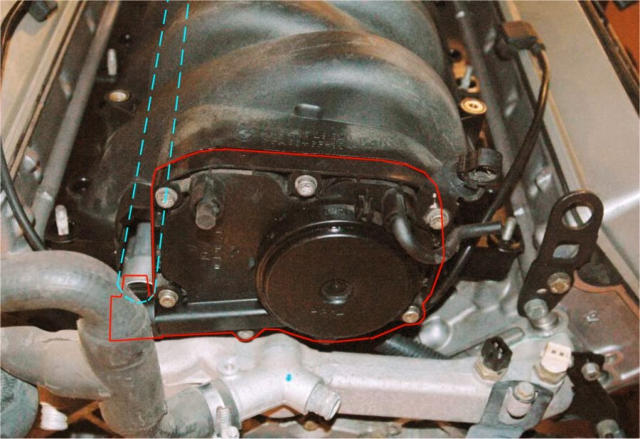

Above is the PCV or Pressure Control Valve, it is fitted to the rear of the Inlet Manifold

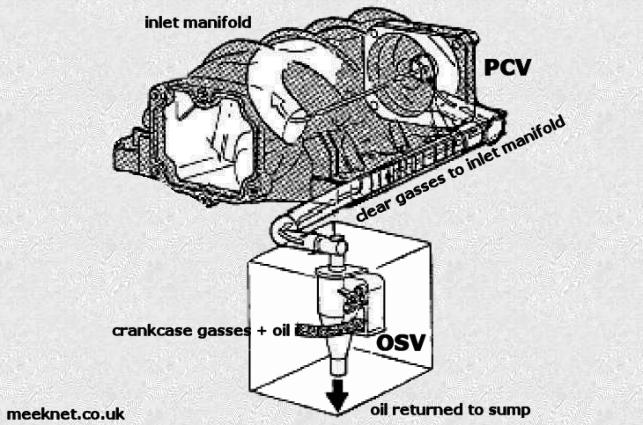

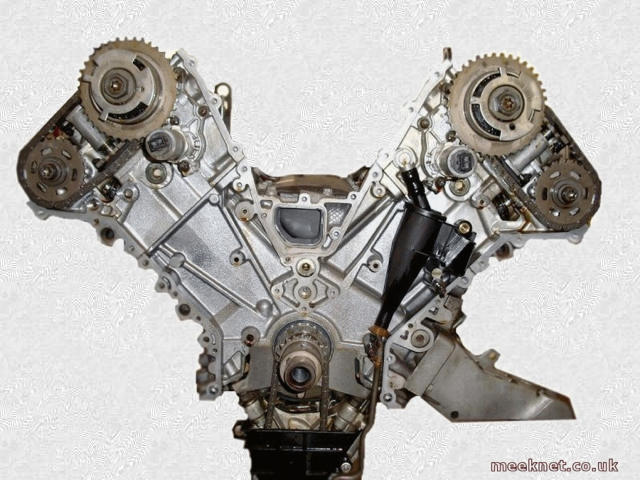

The picture above shows how the system is connected, the oil separator valve (OSV) is housed in the crankcase. Blow-by gasses mixed with

oil vapour enter the OSV under vacuum provided by the inlet manifold, the cyclone action of the OSV spins oil from the vapour, the oil drains

back to the sump. The clear gasses pass through the vent tube, through the PCV and into the manifold.

The PCV at the rear of the crankcase contains a pressure control valve that is set to provide a slight vacuum at the vent tube of 10-15

millibars (equivalent to 6" of water). This regulation of vacuum is important, to deep a vacuum and oil will be drawn from the crankcase, too

little and the cyclone action will not function efficiently.

Below are photographs of the PCV and OSV fitted to the M62TUB engine:

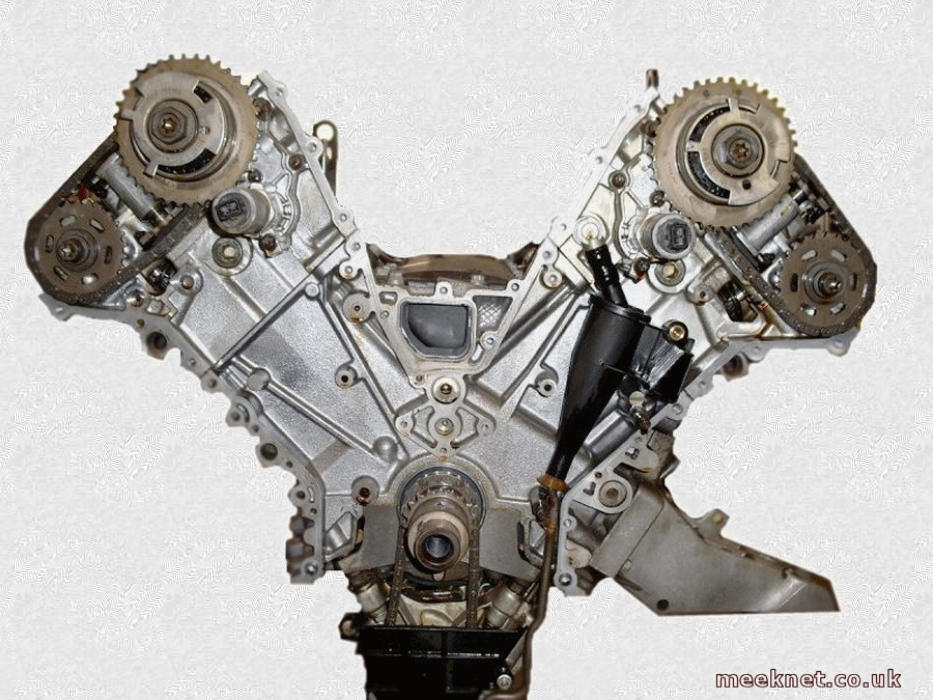

The OSV can be seen here below the cam drives of Bank 2, the metal pipe at the bottom returns the oil to the sump

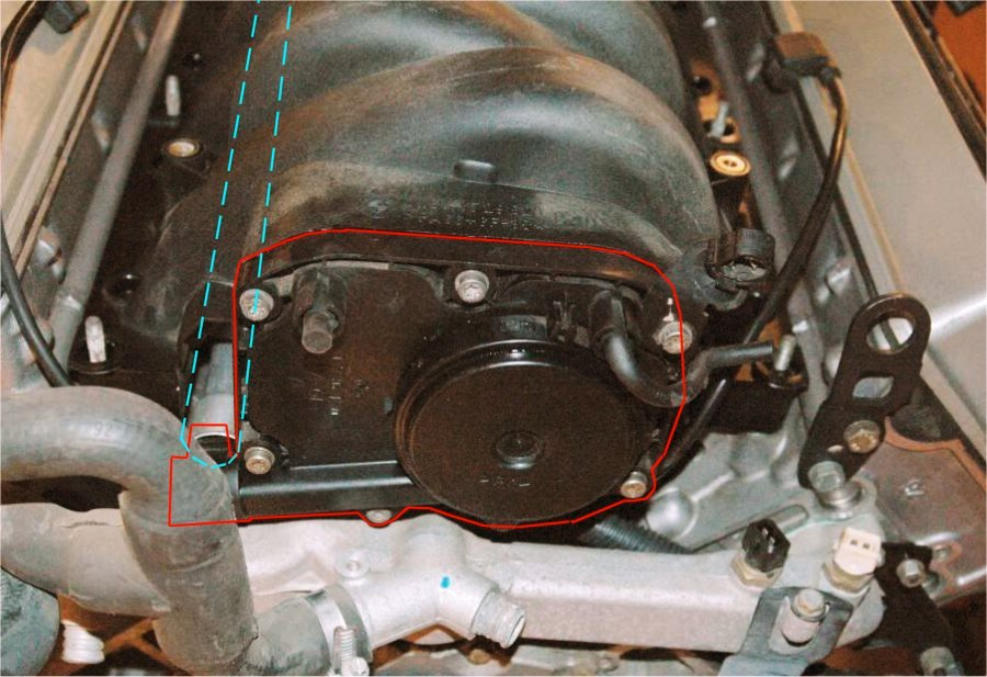

Above is an unusual view, the rear of the M60 showing the PCV (red outline) and vent pipe (blue outline) on the rear of the manifold.

Problems associated with the crankcase ventilation system

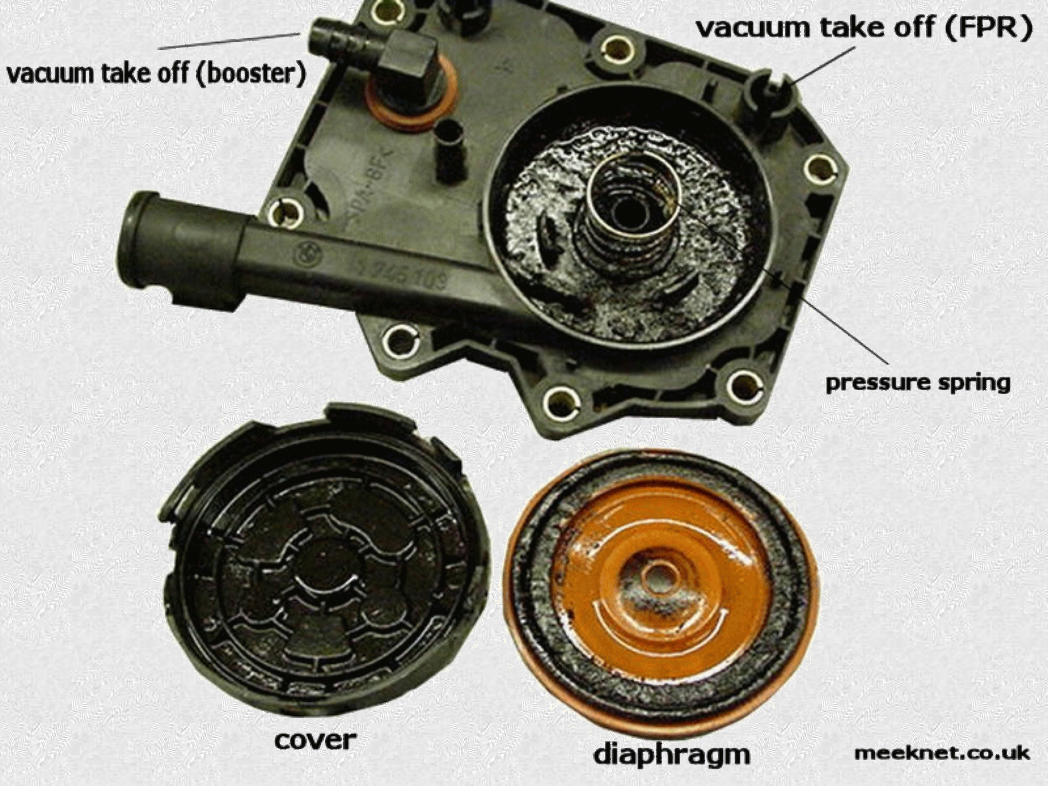

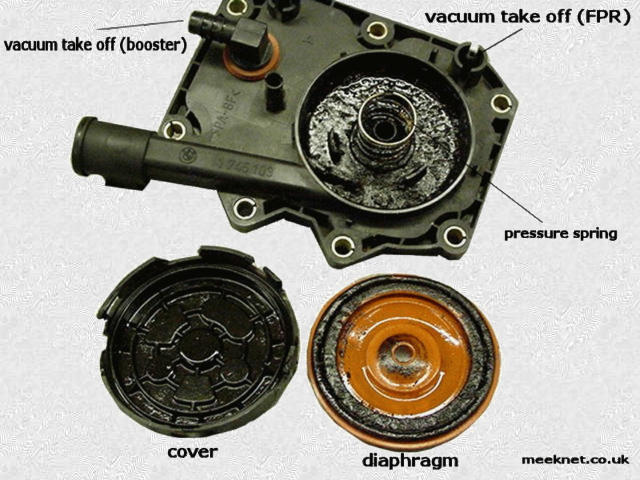

The rear cover has been removed on this PCV, revealing burnt oil and a brittle diaphragm

The PCV above is pretty typical, the diaphragm is brittle, probably split around the rim, and the cavity is full of burnt oil. The spring in the

middle is what sets the crankcase pressure, the inlet manifold vacuum pulls the diaphragm towards the spring, as it moves forward it

restricts the central pipe which leads to the manifold, and that reduces the vacuum at the diaphragm. The vacuum on the diaphragm and

spring pressure from the other direction regulates the crankcase pressure to 10-15 millibar.

If you have any of the problems below, read on!

•

High oil consumption

•

Blue smoke on cold starts

•

Blue smoke under acceleration

•

Poor idle

•

Misfires

•

Error Codes P0170, P0173, P0300, P1174, P1175, P1340

•

Howling noises from the rear of the engine

Above is the OSV or Oil Separator Valve which is housed behind Bank 2's upper timing chain cover

The N62 engines have the OSV built into the valve covers

Above, there are two OSV’s and two PCV’s on the N62 engine as fitted to the E63/E64/E65. Note: The Oil

Separator Valve on the N series V8's is built into the cover above

Problems associated with the crankcase ventilation system

•

High oil consumption

•

Blue smoke on cold starts

•

Blue smoke under acceleration

•

Poor idle

•

Misfires

•

Error Codes P0170, P0173, P0300, P1174, P1175, P1340

•

Howling noises from the rear of the engine

•

Poor pickup under light acceleration (N62)

The list of problems above are often caused by a faulty crankcase ventilation system, and others. The weak spot is the PCV valve which is

fitted to the rear of the inlet manifold. Below is another failed one:

Two failed PCV’s on my N62TUB48

Yes, even on the new range of BMW engines the PCV’s are still getting gummed-up, torn and frizzled. This caused a poor pick-up

under light acceleration. Symptoms are slightly different on the ‘N’ range of engines as the throttle butterfly is normally fully open

and the aspiration is controlled by the Valvetronic valve lift - that means less manifold vacuum

The PCV fails in a number of ways

The diaphragm cracks and disintegrates - this allows un-metered air into the manifold. This fault leads to a number of problems,

poor idle, multiple misfires, adaptations reached limits, pre-cat O2 errors.

The diaphragm sticks to the rear cover - this increases crankcase vacuum and pulls oil into the manifold through the oil-separator

valve due to the disturbance of cyclonic action This is the cause of the plumes of smoke that scare most people to death. It also

coats the inside of the inlet manifold with oil that slops around and produces more smoke when cornering or braking.

The diaphragm sticks to the central manifold pipe or the vent tubes are blocked with old oil - this causes excess crankcase

pressure This fault is not immediately obvious, but is often the cause of oil leaks at the crankshaft front and rear seals. It also

increases the oil leaks from the rocker covers.

Finally, regarding the crankcase ventilation system:

Should removing the dipstick produce a gurgling noise?

The answer is it depends on the amount and viscosity of the oil in the sump. The vacuum in the crankcase should be 10-15 millibars

(up to 27 millibars for the N62xxx engines), so air will be drawn into the crankcase via the dipstick tube, whether it makes a noise is

dependant on the oil level reaching the end of the tube, viscosity and temperature of the oil.

Should removing the oil filler cap change the idle speed?

Yes, it should as un-metered air is reaching the inlet manifold, you will also get a good spray of oil from the timing chain!

Should it be difficult to remove the oil filler cap with the engine running? It needs around a 8oz pull to remove the cap when

the internal vacuum is at the correct 10-15 millibars.

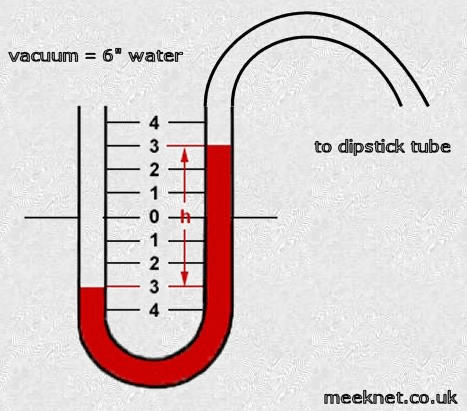

How can the PCV be tested for correct operation?

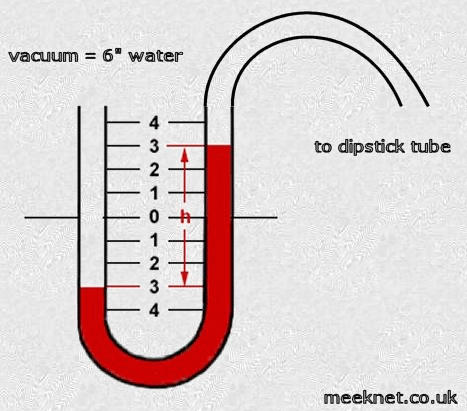

By checking the crankcase vacuum. This can be checked using a vacuum gauge at the dipstick tube, or, as BMW does, use a modified

oil cap with a pressure take-off point screwed into it. Alternatively, a really simple test can be made by using a 1-metre length of

clear tube that fits snugly in the dipstick tube, filled with a few cc's of engine oil and arranged as below:

A simple manometer made from clear tube with a few cc's of engine oil and stuck firmly in the dipstick tube

With the engine idling, the available vacuum in the crankcase should lift 6" of water - that is, a 3" drop and a 3" lift as shown above - the

weight of oil is very similar to water and you will get the same readings without the possibility of getting water in the engine. If there is no

vacuum, then the oil will stay level, if the vacuum is too high the oil may be drawn from the tube. A reading between 4" and 8" is acceptable.

If the reading is outside these readings, or outside 10-15 millibars as read on a vacuum gauge, then it is most likely that the PCV has failed.

A very low vacuum may indicate a vacuum leak, but the leak would have to be reasonably large to defeat a correctly working ventilation

system.

Replacement of the PCV is covered here

Differences between M60/M62/M62TUB manifold PCV system

There are subtle differences between the inlet manifold's used on the different versions of the modern BMW V8. On the M60, the PCV

releases the filtered blow-by gasses directly into the rear of the inlet manifold. This has the effect of allowing the gasses (which still contain a

small amount of oil vapour even on a fully working system) into the rear two cylinders. This can make the rear two cylinders run leaner than

the rest of the cylinders - but also receive the greater amount of oil. This doesn't usually cause much of a problem, but does slightly affect

the tick-over. Once the PCV diaphragm fails, the rear two cylinders will get all the oil and usually have the plugs fouled.

The inlet manifold on the M62 and M62TUB has an additional pipe that runs internally from the PCV to a mixing chamber at the front of the

manifold. This mixes the blow-by gasses with the incoming air from the throttle body - the intention is to ensure that all cylinders receive

their share of the gasses and the small amount of oil vapour from the PCV.

In addition to changes in the crankcase ventilation system, there have also been changes to the runners within the manifold. The runners

sweep from the central plenum of the manifold in a curve to each cylinder. The diameter of the runners have an affect on the performance of

the engine. At the most basic level, the smaller the diameter of the runners, the better the engine will perform at tick-over and at low revs,

the larger the diameter, the more air is available at full-throttle creating more power.

In particular, the diameter of the runners was reduced to increase the velocity of the air in the M62TUB manifold - this was one of

the changes to increase the torque at low-revs and to smooth the tick-over. The increased velocity allows the air in each runner to compress

rather than remain static when the inlet valves are closed, allowing a predictable charge of air into the cylinder. Where larger runners are

employed (as on the M60), the air becomes static in the runner after the inlet valve is closed, and this reduces the available charge as the

valves open leading to poor performance at tick-over and low revs. The reduction in runner diameter increased economy, power and

smoothness in the M62TUB engine.

An internal view of the inlet manifold from an E32 740i - not only large runners but horns as well - a rare find at the scrap yard

A popular modification to the M62TUB44 is to replace the original manifold with one from an E32 740i which not only has larger runners, but

also has trumpets (or horns) at the start of each runner within the plenum. The intention is to increase the power from the engine at full

throttle - and in that, it succeeds. The problem is that the only benefit is felt at full-throttle and at high revs, in all other conditions it

reduces the performance of the engine. It uses more fuel, the torque is decreased at low to medium revs, and the tick-over returns to that of

the M60 - lumpy! The lack of torque at low to medium revs reduces the acceleration of the 740i fitted with the M62TUB44 engine and the

M60B40 inlet manifold, although it does feel more powerful above 4000 RPM.

Other problems with the crankcase ventilation system

The vent pipe on the M62TUB engines can leak on the flexible joint between the pipe and the OSV connection. This can lead to the same

problems as a cracked diaphragm. If, after replacement of the PCV, the car fails to start correctly and has wild changes is revs at tick-over,

this is very often due to the failure to replace the vent pipe correctly. Often the front end of the vent pipe has failed to fit the OSV union and

is just dangling on the block.

A brief history of crankcase ventilation

The crankcase ventilation system causes a few problems - especially when it comes to the correct names for the two main parts of it!

Crankcase ventilation in the 1960's was pretty straightforward, it consisted of an oil-filler cap that was hollow with a lump of foam stuck in

it and a vent to the outside. This allowed the blow-by gasses from the crankcase (the gasses that were forced past the piston rings) to

vent to the outside rather than pressurise the crankcase, the oil vapour that is contained in these gasses was caught (to some extent) by

the foam inside the oil-filler cap.

Later advances used a similar system, but the gasses were returned to the inlet manifold after the throttle butterfly where any residual oil

vapour was burnt during normal combustion in the cylinders. One problem with this new scheme was that at high revs, with the throttle

closed (as when de-accelerating from high speed), the inlet manifold vacuum was very deep - and this pulled oil from the crankcase which

was burnt in the cylinders once the throttle was opened again. This produced plumes of blue smoke, fouled sparkplugs and would have

destroyed the catalytic converters that were destined to be fitted to all cars in the near future. A better scheme was required for BMW's

new V8's.

The BMW V8 crankcase ventilation system

The system used on the BMW V8's has two major changes to the scheme's discussed above.

•

Instead of a lump of foam to catch the oil vapours, a cyclone-separator is used (OSV)

•

To stop oil being drawn from the engine at high manifold vacuum, a pressure-control valve is used (PCV)

Here are the two main parts:

SEARCH MEEKNET

SEARCH MEEKNET

Timm's The BMW M60 M62

M62TUB and N62TUB Engine

Crankcase Ventilation - OSV and PCV

Above is the PCV or Pressure Control Valve, it is fitted

to the rear of the Inlet Manifold

The picture above shows how the system is connected, the oil separator

valve (OSV) is housed in the crankcase. Blow-by gasses mixed with oil

vapour enter the OSV under vacuum provided by the inlet manifold, the

cyclone action of the OSV spins oil from the vapour, the oil drains back to

the sump. The clear gasses pass through the vent tube, through the PCV

and into the manifold.

The PCV at the rear of the crankcase contains a pressure control valve

that is set to provide a slight vacuum at the vent tube of 10-15 millibars

(equivalent to 6" of water). This regulation of vacuum is important, to

deep a vacuum and oil will be drawn from the crankcase, too little and the

cyclone action will not function efficiently.

Below are photographs of the PCV and OSV fitted to the M62TUB engine:

The OSV can be seen here below the cam drives of Bank 2, the metal pipe at the bottom

returns the oil to the sump

Above is an unusual view, the rear of the M60 showing the PCV (red outline) and vent pipe

(blue outline) on the rear of the manifold.

Problems associated with the crankcase ventilation system

The rear cover has been removed on this PCV, revealing burnt oil

and a brittle diaphragm

The PCV above is pretty typical, the diaphragm is brittle, probably split

around the rim, and the cavity is full of burnt oil. The spring in the middle

is what sets the crankcase pressure, the inlet manifold vacuum pulls the

diaphragm towards the spring, as it moves forward it restricts the central

pipe which leads to the manifold, and that reduces the vacuum at the

diaphragm. The vacuum on the diaphragm and spring pressure from the

other direction regulates the crankcase pressure to 10-15 millibar.

If you have any of the problems below, read on!

•

High oil consumption

•

Blue smoke on cold starts

•

Blue smoke under acceleration

•

Poor idle

•

Misfires

•

Error Codes P0170, P0173, P0300, P1174, P1175, P1340

•

Howling noises from the rear of the engine

Above is the OSV or Oil Separator Valve which is housed

behind Bank 2's upper timing chain cover

The N62 engines have the OSV built into the valve covers

Above, there are two OSV’s and two PCV’s on the N62

engine as fitted to the E63/E64/E65. Note: The Oil

Separator Valve on the N series V8's is built into the cover

above

Problems associated with the crankcase ventilation system

•

High oil consumption

•

Blue smoke on cold starts

•

Blue smoke under acceleration

•

Poor idle

•

Misfires

•

Error Codes P0170, P0173, P0300, P1174, P1175, P1340

•

Howling noises from the rear of the engine

•

Poor pickup under light acceleration (N62)

The list of problems above are often caused by a faulty crankcase

ventilation system, and others. The weak spot is the PCV valve which is

fitted to the rear of the inlet manifold. Below is another failed one:

Two failed PCV’s on my N62TUB48

Yes, even on the new range of BMW engines the PCV’s are still getting

gummed-up, torn and frizzled. This caused a poor pick-up under light

acceleration. Symptoms are slightly different on the ‘N’ range of engines

as the throttle butterfly is normally fully open and the aspiration is

controlled by the Valvetronic valve lift - that means less manifold vacuum

The PCV fails in a number of ways

The diaphragm cracks and disintegrates - this allows un-metered air

into the manifold. This fault leads to a number of problems, poor idle,

multiple misfires, adaptations reached limits, pre-cat O2 errors.

The diaphragm sticks to the rear cover - this increases crankcase

vacuum and pulls oil into the manifold through the oil-separator valve due

to the disturbance of cyclonic action This is the cause of the plumes of

smoke that scare most people to death. It also coats the inside of the inlet

manifold with oil that slops around and produces more smoke when

cornering or braking.

The diaphragm sticks to the central manifold pipe or the vent tubes

are blocked with old oil - this causes excess crankcase pressure This fault

is not immediately obvious, but is often the cause of oil leaks at the

crankshaft front and rear seals. It also increases the oil leaks from the

rocker covers.

Finally, regarding the crankcase ventilation system:

Should removing the dipstick produce a gurgling noise?

The answer is it depends on the amount and viscosity of the oil in the

sump. The vacuum in the crankcase should be 10-15 millibars (up to 27

millibars for the N62xxx engines), so air will be drawn into the crankcase

via the dipstick tube, whether it makes a noise is dependant on the oil

level reaching the end of the tube, viscosity and temperature of the oil.

Should removing the oil filler cap change the idle speed?

Yes, it should as un-metered air is reaching the inlet manifold, you will

also get a good spray of oil from the timing chain!

Should it be difficult to remove the oil filler cap with the engine

running? It needs around a 8oz pull to remove the cap when the internal

vacuum is at the correct 10-15 millibars.

How can the PCV be tested for correct operation?

By checking the crankcase vacuum. This can be checked using a vacuum

gauge at the dipstick tube, or, as BMW does, use a modified oil cap with a

pressure take-off point screwed into it. Alternatively, a really simple test

can be made by using a 1-metre length of clear tube that fits snugly in the

dipstick tube, filled with a few cc's of engine oil and arranged as below:

A simple manometer made from clear tube with a few cc's of

engine oil and stuck firmly in the dipstick tube

With the engine idling, the available vacuum in the crankcase should lift

6" of water - that is, a 3" drop and a 3" lift as shown above - the weight

of oil is very similar to water and you will get the same readings without

the possibility of getting water in the engine. If there is no vacuum, then

the oil will stay level, if the vacuum is too high the oil may be drawn

from the tube. A reading between 4" and 8" is acceptable. If the reading

is outside these readings, or outside 10-15 millibars as read on a

vacuum gauge, then it is most likely that the PCV has failed. A very low

vacuum may indicate a vacuum leak, but the leak would have to be

reasonably large to defeat a correctly working ventilation system.

Replacement of the PCV is covered here

Differences between M60/M62/M62TUB manifold PCV system

There are subtle differences between the inlet manifold's used on the

different versions of the modern BMW V8. On the M60, the PCV releases

the filtered blow-by gasses directly into the rear of the inlet manifold.

This has the effect of allowing the gasses (which still contain a small

amount of oil vapour even on a fully working system) into the rear two

cylinders. This can make the rear two cylinders run leaner than the rest

of the cylinders - but also receive the greater amount of oil. This doesn't

usually cause much of a problem, but does slightly affect the tick-over.

Once the PCV diaphragm fails, the rear two cylinders will get all the oil

and usually have the plugs fouled.

The inlet manifold on the M62 and M62TUB has an additional pipe that

runs internally from the PCV to a mixing chamber at the front of the

manifold. This mixes the blow-by gasses with the incoming air from the

throttle body - the intention is to ensure that all cylinders receive their

share of the gasses and the small amount of oil vapour from the PCV.

In addition to changes in the crankcase ventilation system, there have

also been changes to the runners within the manifold. The runners

sweep from the central plenum of the manifold in a curve to each

cylinder. The diameter of the runners have an affect on the performance

of the engine. At the most basic level, the smaller the diameter of the

runners, the better the engine will perform at tick-over and at low revs,

the larger the diameter, the more air is available at full-throttle creating

more power.

In particular, the diameter of the runners was reduced to increase

the velocity of the air in the M62TUB manifold - this was one of the

changes to increase the torque at low-revs and to smooth the tick-over.

The increased velocity allows the air in each runner to compress rather

than remain static when the inlet valves are closed, allowing a

predictable charge of air into the cylinder. Where larger runners are

employed (as on the M60), the air becomes static in the runner after the

inlet valve is closed, and this reduces the available charge as the valves

open leading to poor performance at tick-over and low revs. The

reduction in runner diameter increased economy, power and smoothness

in the M62TUB engine.

An internal view of the inlet manifold from an E32 740i - not only

large runners but horns as well - a rare find at the scrap yard

A popular modification to the M62TUB44 is to replace the original manifold

with one from an E32 740i which not only has larger runners, but also has

trumpets (or horns) at the start of each runner within the plenum. The

intention is to increase the power from the engine at full throttle - and in

that, it succeeds. The problem is that the only benefit is felt at full-throttle

and at high revs, in all other conditions it reduces the performance of the

engine. It uses more fuel, the torque is decreased at low to medium revs,

and the tick-over returns to that of the M60 - lumpy! The lack of torque at

low to medium revs reduces the acceleration of the 740i fitted with the

M62TUB44 engine and the M60B40 inlet manifold, although it does feel

more powerful above 4000 RPM.

Other problems with the crankcase ventilation system

The vent pipe on the M62TUB engines can leak on the flexible joint

between the pipe and the OSV connection. This can lead to the same

problems as a cracked diaphragm. If, after replacement of the PCV, the

car fails to start correctly and has wild changes is revs at tick-over, this is

very often due to the failure to replace the vent pipe correctly. Often the

front end of the vent pipe has failed to fit the OSV union and is just

dangling on the block.

A brief history of crankcase ventilation

The crankcase ventilation system causes a few problems - especially when

it comes to the correct names for the two main parts of it! Crankcase

ventilation in the 1960's was pretty straightforward, it consisted of an oil-

filler cap that was hollow with a lump of foam stuck in it and a vent to the

outside. This allowed the blow-by gasses from the crankcase (the gasses

that were forced past the piston rings) to vent to the outside rather than

pressurise the crankcase, the oil vapour that is contained in these gasses

was caught (to some extent) by the foam inside the oil-filler cap.

Later advances used a similar system, but the gasses were returned to

the inlet manifold after the throttle butterfly where any residual oil vapour

was burnt during normal combustion in the cylinders. One problem with

this new scheme was that at high revs, with the throttle closed (as when

de-accelerating from high speed), the inlet manifold vacuum was very

deep - and this pulled oil from the crankcase which was burnt in the

cylinders once the throttle was opened again. This produced plumes of

blue smoke, fouled sparkplugs and would have destroyed the catalytic

converters that were destined to be fitted to all cars in the near future. A

better scheme was required for BMW's new V8's.

The BMW V8 crankcase ventilation system

The system used on the BMW V8's has two major changes to the

scheme's discussed above.

•

Instead of a lump of foam to catch the oil vapours, a cyclone-

separator is used (OSV)

•

To stop oil being drawn from the engine at high manifold vacuum, a

pressure-control valve is used (PCV)

Here are the two main parts:

SEARCH MEEKNET

SEARCH MEEKNET